Navigating the challenges of distribution requires not just improvement, but continuous improvement to achieve the best outcomes. Referred to as CI, continuous improvement encompasses various strategies to drive meaningful and lasting returns on investment. By following best practices, businesses can ensure their improvement efforts yield significant results over time.

Whether a student of Six Sigma, Lean, Kaizen, or none of these, this article outlines three key components of a successful CI project. Before jumping into the singular details, it’s important to note that companies with a CI mindset, incorporating it as part of the overall business strategy, stand to benefit the most. While one-off improvement projects have value, adopting a comprehensive CI mindset ensures improvement opportunities are consistently identified and leveraged to drive the business forward.

Accurately Define the Problem/Opportunity and Determine the Root Cause

Every process is a candidate for a CI study, even if there are no obvious signs of trouble. When quality or productivity issues are evident — such as missed deadlines or unsatisfied customers — it’s time to initiate a CI study. Additionally, encouraging a culture of curiosity, where employees constantly seek better ways to do things, can lead to significant improvements. For example, exploring back-office functions that might benefit from adopting new technologies can yield hidden opportunities.

To start, clearly define the problem or opportunity for improvement. A poorly defined problem statement will not generate the desired results. Once the problem/opportunity has been described, focus on identifying the root cause(s). Why is productivity down or quality suffering? Why are customers dissatisfied? Why is the back office overwhelmed with data entry tasks instead of focusing on more critical projects? Uncovering the root cause often requires collaboration and dialogue with on-site teams. In most cases, the improvement team will ask “Why” five times before the true root cause is identified. A few days of discussion and exploration should help identify the root issue and influence next steps.

This process could involve reviewing invoice and production data from a company’s enterprise resource planning (ERP) and production systems, shadowing a project team or broadening discussions to include vendors and customers. Additionally, leveraging real-time data and AI-driven analytics can help identify inefficiencies more quickly. With the right research, CI projects become more targeted and effective.

For example, after discussing challenges with a team earlier this year, we discovered the root cause of production delays was an inefficient equipment layout. By optimizing the placement of materials and machinery, the company achieved an annual savings of $180,000. While the solution involved more than just rearranging the shop floor, this relatively simple fix produced substantial returns.

Tailor the Tactics

Once the root cause is identified, the real work begins. Because there is no one-size-fits all solution, especially if the goal is lasting improvement, it is important to test new approaches through pilot tests. Once a solution proves effective, begin to expand it into a full implementation.

Even if two distribution companies use the same order management system, they may not benefit from identical CI processes. Tailoring the solution to address the specific root cause of inefficiencies or quality issues is critical for achieving long-term success.

Consider an example project focused on optimizing and automating sales order entry. For a company that receives standardized purchase orders from customers, implementing an optical character recognition (OCR) system could streamline the process. The OCR system can then translate the purchase orders into sales orders, significantly reducing data entry time and reducing keypunch errors.

Measure Results

A CI project isn’t truly complete once a solution is implemented. To ensure lasting success, it’s critical to establish metrics that measure the impact of the improvements. After the implementation phase, re-evaluate the improvements 30, 60 and even 90 days later to ensure the solution remains effective. Are costs under control? Has the problem been resolved? Is the process more efficient?

CI projects should provide tangible benefits such as cost savings, improved efficiency and customer satisfaction. They can also give distribution companies a competitive advantage.

One way to measure the return is by looking at one of the most commonly and continually monitored metrics – on time and in full (OTIF). In the lumber and building materials industry, an OTIF rate of 95 percent is considered good, though not great. Other measurements might include cycle time, fill rate or order accuracy.

In the case of a truss manufacturer, the lead production manager found that much of the lumber they received was unsuitable for trusses but could be useful for non-structural products. Instead of throwing out the product, the company re-purposed it to create pallets, which reduced their dumpster pickups from twice a week to only one. The cost to make this change? Zero. The benefits? Significant material and cost savings.

Breaking Down Hierarchies for Success

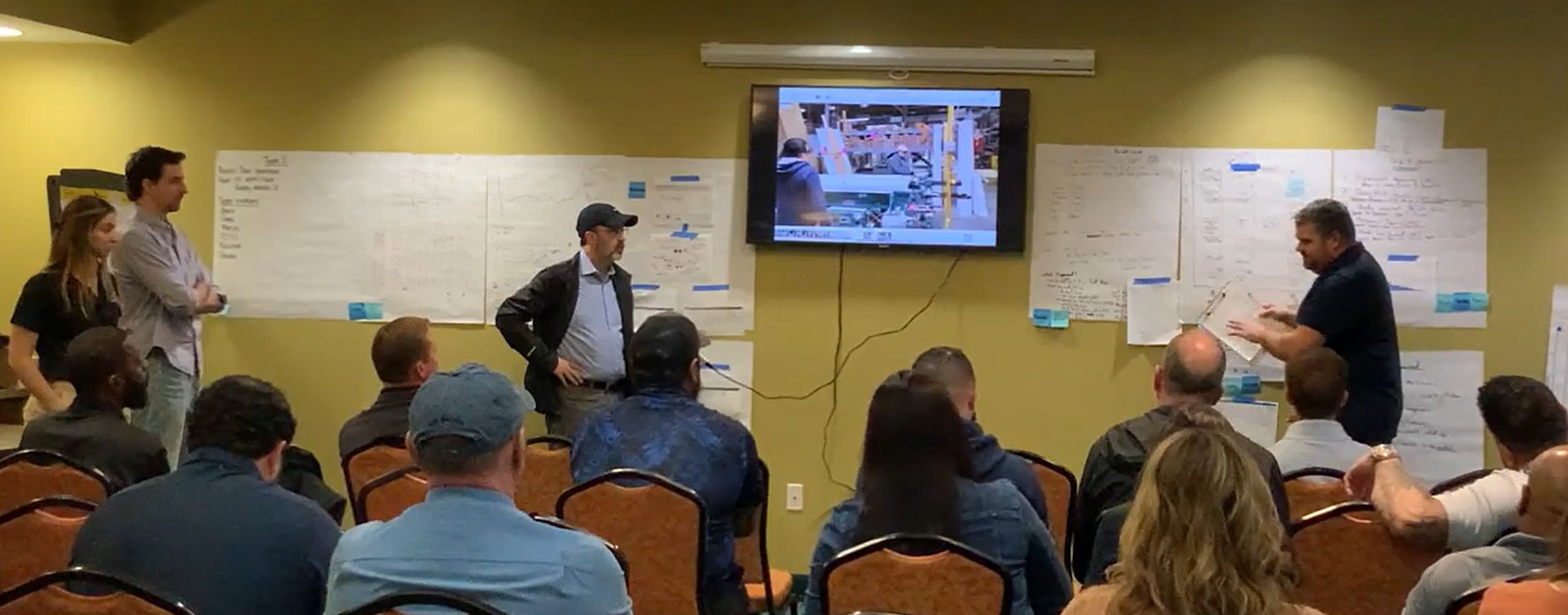

CI projects benefit greatly from the best practices discussed here, but there is one more element worth mentioning. Any CI project will be most successful if it is conducted top down and bottom up. Engaging all levels of the business, from executives to on-the-ground employees, will result in company-wide buy-in. Companies that value collaboration, innovation and employee empowerment are more likely to build a culture of continuous improvement, where each team member feels empowered to contribute ideas. This approach can drive innovation from the ground up and lead to a faster return on investment, often within a year or less.

Upon completion of each CI project, be sure to learn from the experience. Determining the root cause should make it easier to tackle the next inefficiency, tailoring the project to fit the unique scenario will increase the likelihood of success, and measuring the results over time will confirm the project was worth the effort. When the entire team is engaged, companies can achieve greater efficiency, customer satisfaction, and overall success.

Related Posts

-

Great Lake Fasteners expands into the Atlantic and southern states with its newest acquisition of…

-

The MRO supplies distributor has a new U.S. President, Global Integrated Supply President and Chief…

-

Two VPs from fasteners distributor and manufacturer Optimas Solutions discuss personally-vetted supply chain management strategies…