Marie Donlon | July 14, 2022

Researchers from the Chinese Academy of Sciences’ (CAS’) Shanxi Institute of Coal Chemistry have developed a new membrane separation technique using two different cellulose materials for potentially cleaning up oil spills and industrial pollution.

The new process reportedly enabled the researchers to develop low cost, environmentally friendly, plant-derived membrane materials for oil-water separation.

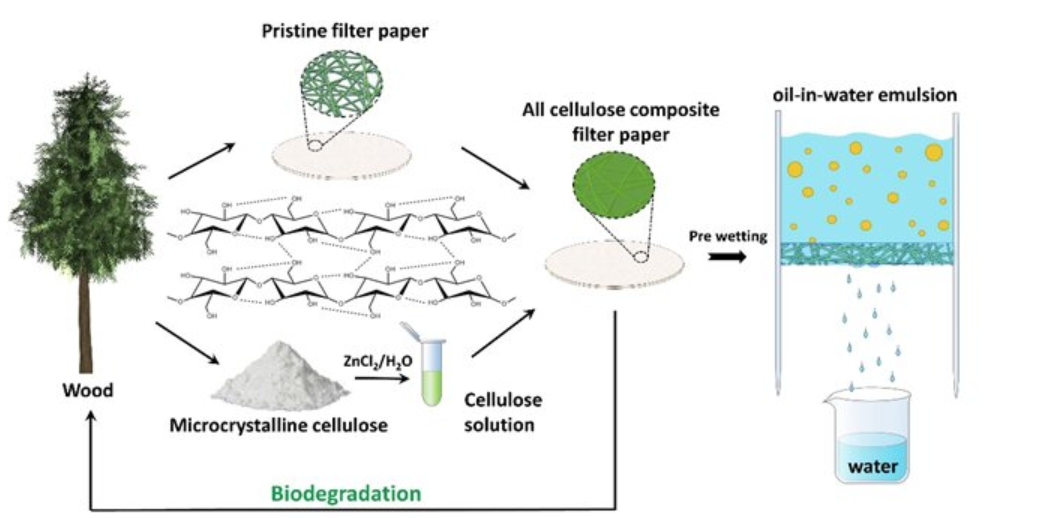

The closed loop process of the degradable cellulose oil-water separation membrane. Source: Institute of Coal Chemistry (CAS)

The closed loop process of the degradable cellulose oil-water separation membrane. Source: Institute of Coal Chemistry (CAS)

The researchers took degradable cellulose and then bonded it with commercial cellulose filter paper to create the membrane that achieved a high level of separation. According to the team, this high level of separation was due to the large number of nanopores that appeared in the modified cellulose filter paper, which reportedly improved the membrane’s barrier against oil droplets.

In the lab, the separation membrane was put into contact with water, thereby creating a cellulose hydrogel that separated the oil-water mixture and oil in water emulsion.

The researchers explained: “Cellulose chains are tightly bonded by a hydrogen bond, with few defects, and the mechanical properties of the material are greatly improved. The high dry and wet mechanical properties of the membrane extend the ways in which it can be applied and help it to remain stable when used in water. We believe this is an important step forward in the treatment of pollution.”

The study, Efficient oil-water separation by novel biodegradable all cellulose composite filter paper, appears in the journal Green Energy & Environment.