N. Mughees | August 23, 2024

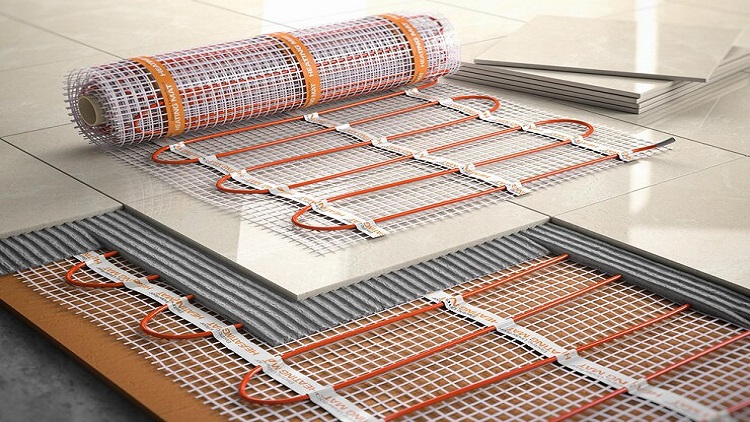

Mat electric heating system. Source: Maksym Yemelyanov/Adobe Stock

Mat electric heating system. Source: Maksym Yemelyanov/Adobe Stock

Heating is the transfer of thermal energy from a hotter object to a colder one. It’s the movement of heat that makes things feel warm. Electrical heating is the process of converting electricity into heat. This is done through a principle called Joule heating, where electricity flowing through a conductor (usually with high resistance) generates heat. The use of a potential difference or induced eddy currents is directly responsible for the circulation of this electric current. Electric heating can be performed using various methods, each with its own advantages and disadvantages as discussed in this article.

Resistance heating

This is the most common type of electric heating, and it works based on a scientific principle called Joule heating as just explained. When electricity passes through a conductor with high resistance, it encounters opposition to the flow of current. This opposition translates into heat generation. Resistance heating elements are typically made from materials with high resistivity, meaning they resist the flow of electricity well. For example, a nickel-chromium alloy is commonly used as it is known for its durability and ability to withstand high temperatures. Resistance heating is used in a variety of appliances and heating systems such as:

- Electric furnaces and baseboard heaters: These use resistance coils to heat air, which is then distributed through a home.

- Toasters and ovens: The coils inside get hot due to resistance heating, toasting bread or baking food.

- Hair dryers and clothes irons: Similar concept — the heating elements get hot and transfer heat to dry hair or clothes.

- E-cigarette atomizers: The coil heats up, vaporizing the e-cigarette liquid.

Advantages of resistance heating:

- Simple and reliable technology: Been around for a long time and is well-understood.

- Relatively inexpensive: Due to the straightforward design of heating elements.

- Easy to control: The amount of heat produced can be easily regulated by controlling the electric current.

Disadvantages of resistance heating:

- Can be less efficient: Especially compared to heat pumps, all the energy goes into heating the element, with some heat loss during transfer.

- Slow heating response: It takes some time for the element to heat up and reach the desired temperature.

Arc heating

Arc heating utilizes the intense heat generated by an electric arc for various industrial processes. An electric arc is a continuous flow of electricity through a gas that becomes ionized (charged particles) due to the high temperature. This ionized gas has very low resistance, allowing electricity to flow and creating an intense heat source. The temperature within an electric arc can reach several thousand degrees Celsius. It is useful particularly for high-temperature processes like:

- Electric arc furnace (EAF): The most common application. EAFs use electric arcs to melt and refine metals, especially steel. The intense heat from the arc directly melts the scrap metal and allows for precise control over the temperature for refining purposes.

- Plasma torches: These focused streams of high-temperature plasma generated by an electric arc are used for cutting, welding and spraying molten materials onto surfaces.

- Glass production: Arc heating can be used to melt raw materials for glass manufacturing.

Types of arc heaters:

There are two main categories of arc heaters based on the electrode configuration:

- Direct arc furnaces: In these furnaces, the electric arc forms directly between the electrodes and the material being heated. This method offers high heating efficiency as the arc directly heats the charge.

- Indirect arc furnaces: Here, the arc strikes between the electrodes and doesn’t directly contact the material. The heat radiates from the arc to the material being processed. This approach offers better control over contamination but might be less efficient.

Advantages of arc heating:

- High temperatures: Arc heating can achieve incredibly high temperatures, making it suitable for melting very high melting point materials.

- Fast heating: The intense heat from the arc allows for rapid heating of materials.

- Clean and controllable: Electric arc heating doesn’t involve combustion, leading to a cleaner process. The temperature can also be precisely controlled.

Disadvantages of arc heating:

- High energy consumption: Maintaining a continuous arc requires significant electrical power.

- Electrode wear: Electrodes erode over time due to the high temperatures, requiring replacement.

- Complexity: Designing and operating arc heating systems can be complex compared to simpler resistance heating methods.

Induction heating or high frequency heating

In high frequency heating, the operating frequency is much higher than the power line frequency (50 Hz or 60 Hz), ranging from kilohertz (kHz) to megahertz (MHz). Induction cooktops and some advanced inverter-based heating systems utilize this approach.

Advantages:

- Smaller transformers possible due to the higher frequency (more compact equipment)

- Can potentially achieve higher efficiency due to lower switching losses

- Faster heating response

Disadvantages:

- More complex circuit design

- May require more expensive high-frequency components

Conclusion

Electric heating refers to the method of directly converting electrical energy into heat energy. Space heating, water heating, cooking and industrial processes are its common uses. Electric heaters with built-in resistors are the building blocks of these processes. As current flows through it, this resistor uses the principle of Joule heating to transform electrical energy into heat.

INDUSTRY RELATED

UNLIMITED FREE ACCESS TO THE WORLD’S BEST IDEAS

SIGN UP TO SEE MORE

This is embarrasing…

An error occurred while processing the form. Please try again in a few minutes.

Customize Your GlobalSpec Experience

This is embarrasing…

An error occurred while processing the form. Please try again in a few minutes.