The trick is to used both sides of the wafer, and exploit a quirk of GaN.

“GaN is unique among wide-bandgap semiconductors because it has a large electronic polarisation along its crystal axis, which gives each of its surfaces dramatically different physical and chemical properties,” said Cornell. “The gallium side has proved useful for photonic devices such as LEDs and lasers, while the nitrogen side can host transistors.”

“To our knowledge, nobody has made active devices on both sides, not even for silicon,” said Cornell research engineer Len van Deurzen. “One of the reasons is that there’s no additional functionality you get from using both sides of a silicon wafer because it’s cubic – both sides are basically the same.”

The idea was conceived by Cornell’s Professor Debdeep Jena, and Henryk Turski who has positions at Cornell and at the Polish Institute of High Pressure Physics.

What followed was the development of heterostructures and strategies that allowed working devices to be made without the hemts 9high electron mobility transistors) being destroyed by LED fabrication or vice versa.

The Polish Institute was responsible for growing a suitable transparent GaN substrate, then adding the hemt and LED heterostructures using molecular beam epitaxy.

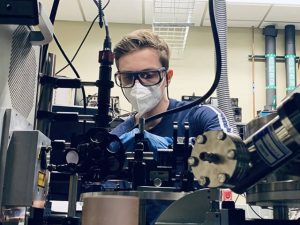

Cornell then created hemts on the nitrogen polar face.

“The nitrogen polar side is more chemically reactive, which means during device processing the electron channel can be damaged quite easily,” said Corenell’s Eungkyun Kim. “A challenge with nitrogen polar transistor fabrication is to make sure all the plasma processes and the chemical treatment do not damage the transistors. So there was a lot of process development that had to be done for fabricating and designing that transistor.”

After this, it was van Deurzen turn to build LEDs on the metal polar face, using a thick positive photo resist coating to protect the previously processed n-polar face.

“It’s actually a very feasible process,” said van Deurzen said. “The devices do not degrade – this is obviously important if you want to use this as a real technology.”

In use, LED shines through the transparent substrate, with its light passing the hemts en-route to the outside world.

The team suggests that its technology might be used to make micro-LED displays, and demonstrated feasibility by wiring the LED in series with the transistor to make an active pixel – using a combination of wire bonds and conductive traces on a supporting glass slide to connect one to the other.

“The single hemt succeeded in driving a large LED, turning it on and off at kilohertz frequencies,” said Cornell.

Possible extensions to the technology are to make lasers instead of LEDs, to add CMOS using polarisation-induced n-channel transistors on one side and p-channel transistors on the other, and to exploiting high piezoelectric coefficient of the GaN substrate to make bulk acoustic wave filters and resonators.

“You could essentially enable the convergence of photonic, electronic and acoustic devices,” said van Deurzen.

This work is described in a very readable paper published Nature: ‘Using both faces of polar semiconductor wafers for functional devices‘, which can be viewed without payment and is well worth browsing even if you are not a specialist.