“Because of the bond exchanges that take place in the material, you can restore a car’s deformations after a collision, and most importantly, significantly improve  vehicle safety by protecting the passenger,” said Mohammad Naraghi (pictured) the college’s professor of aerospace engineering,“these vitrimers, when reinforced with discontinuous fibres, can undergo level cycling — you can easily crush and mould it into a new shape, and this can happen across many, many cycles, and the chemistry of the material basically doesn’t degrade”.

vehicle safety by protecting the passenger,” said Mohammad Naraghi (pictured) the college’s professor of aerospace engineering,“these vitrimers, when reinforced with discontinuous fibres, can undergo level cycling — you can easily crush and mould it into a new shape, and this can happen across many, many cycles, and the chemistry of the material basically doesn’t degrade”.

The researchers applied repeated cycles of tensile, or stretching, loads to samples, monitoring changes in how the material accumulated, stored and released strain energy.Using cyclical loading, the researchers identified two critical temperatures within the material.

The first is the glass transition temperature, or the temperature at which the polymer chains can move around easily, and the second is the vitrification temperature. That’s the temperature at which these bonds are thermally activated enough that you can see massive bond exchanges to cause healing, reshaping and recovery,

The team then conducted deep-cycle bending fatigue tests, periodically heating the material to around 160 degrees Celsius to trigger self-healing.

Their results showed that the ATSP samples not only endured hundreds of stress and heating cycles without failure, but that they actually grew more durable during the healing process.

The team put the heat-resistant ATSP through five gruelling stress cycles, each followed by high temperature exposure at 280 degrees Celsius to assess the material’s performance and self-healing properties.

After two full damage-healing cycles, the material returned to nearly full strength. By the fifth cycle, healing efficiency dropped to about 80% because of mechanical fatigue.

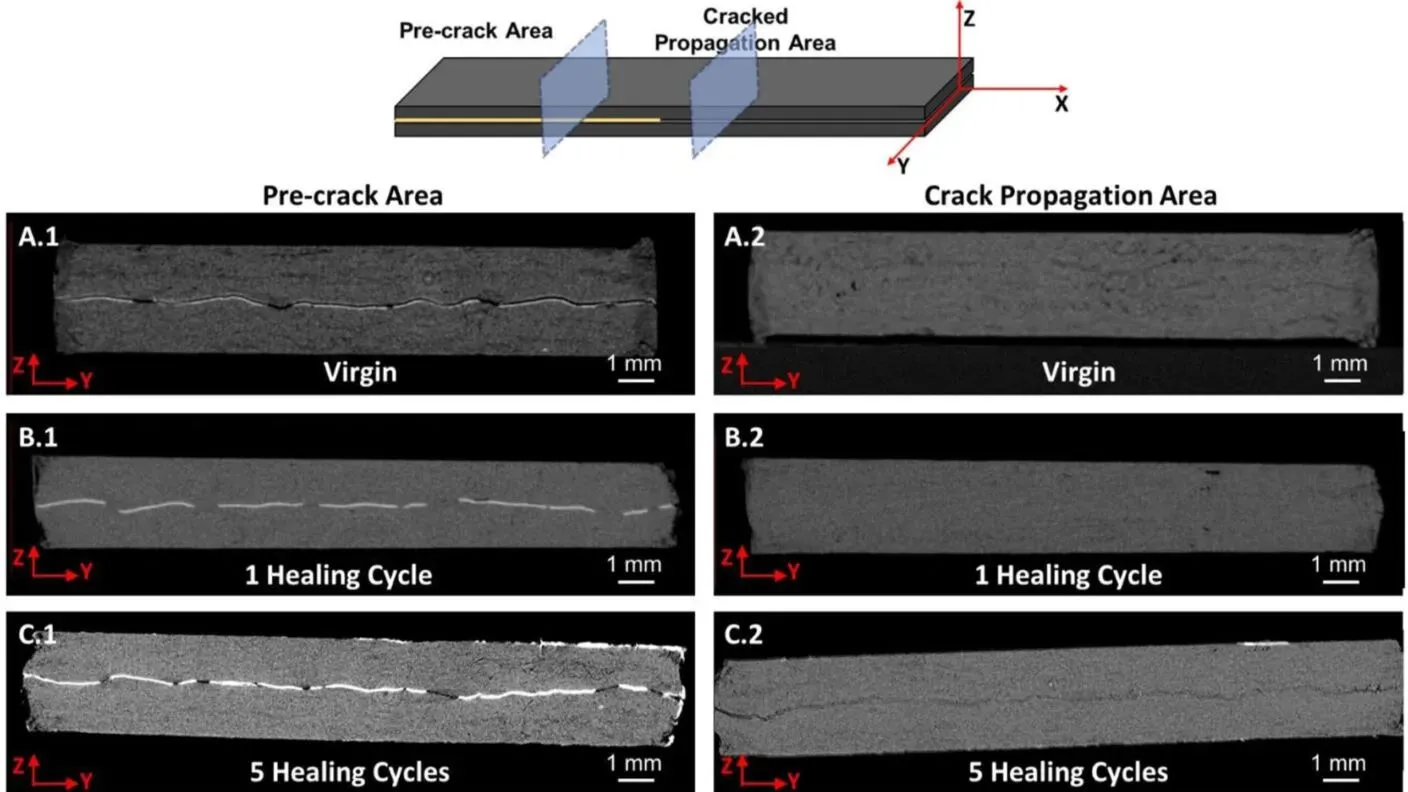

X-ray images of ATSP across five different damage-healing cycles. In the first cycle, the scans revealed that ATSP fully healed and recovered its shape and strength. By the fifth cycle, mechanical fatigue began to appear, though the durability and chemical stability were not affected.

Still, the material’s chemical stability and self-healing behaviours remained reliable across all five cycles. There was no thermal degradation or breakdown in the material, demonstrating its durability even after damage and healing.