Chuck Hanson, Hemmings Motor News | June 12, 2023

There’s considerable consensus that the muscle car era reached its peak in 1970. After that, it seemed the government and insurance companies actively conspired to bring the fun to a halt. Tamed engines outfitted with additional smog equipment were deemed necessary to save the planet, while rising insurance premiums on performance machines sought to save corporate profits… and maybe to save us speed demons from ourselves.

With few exceptions, compression cuts, more conservative camshaft profiles and ignition curves, and other rudimentary emission stopgaps were put into effect across the board by auto manufacturers as they yielded to government mandates. And as any gearhead worth his or her chrome valve covers already knew, these changes resulted in lower performance and higher fuel consumption as the compromised engines struggled to maintain combustion efficiency.

Pontiac had long been touted as GM’s performance division, and its plan to retain that revered position during those transitional times was to drop the compression but keep the cubes. The result was the creation of several notable pump-gas friendly, big-inch engines that may have lacked the impressive horsepower numbers, but generated tons of torque to get the job done. Informed mechanical minds acknowledge without equivocation that torque is what moves mass; in performance circles, the name of the game is to get it moving quickly and maintain it in a state of forward momentum. Certainly, the 455 H.O. is a great example of Pontiac’s intentions.

When first introduced for 1971, the 455 H.O. featured four-bolt mains and a cast crank, rods and pistons. A Quadrajet on a two-piece aluminum intake manifold fed the beast, while the heads featured larger intake ports than the standard 455 paired with Pontiac’s “round-port” exhaust outlets, seen previously on the Ram Air II and Ram Air IV 400 engines. Free-flowing cast-iron exhaust manifolds fed dual exhaust and compression was pegged at just 8.4:1, allowing it to run on the coming regular unleaded fuel.

The initial offering of the 455 H.O. had a gross rating of 335 hp at 4,800 rpm and 480 lb-ft at 3,200 rpm. For ’72, the 455 H.O. was carried over without any significant changes, but the horsepower rating was now presented in net terms: 300 hp at 4,000 rpm and 415 lb-ft at 3,200 rpm. And even though it saw only two years of production, Pontiac illuminati still consider the 455 H.O. the most versatile street engine Pontiac ever produced.

Essential to the ’72 455 H.O. engine’s success were the “7F6” cylinder heads that provided airflow in and out of the engine. Breathing improvements were further enhanced by the “open” combustion chambers that gave the valves even more room to inhale refined fossil fuels and spit out combusted hydrocarbons. When approached with today’s fastidious machining practices and the introduction of a bit of modern technology, this factory package can become an even more robust performer.

Although the heads are already capable of flowing prodigious amounts of air in stock form, enhancements in the form of a three-angle valve job, judicious pocket porting, and stainless valves with undercut stems further improve the flow numbers. Adding a more aggressive camshaft and related valvetrain components that complement the heads’ capabilities also makes sense, and the package is completed by shuttling the factory manifold and Quadrajet carb and replacing them with an intake of updated design and topping it with a Holley fuel mixer.

So, how responsive is the 455 H.O. to those technological updates? We recently found out by following the rebuild of a customer’s otherwise stock example at a performance machine shop, Tommy’s Auto Machine, in Springfield, Tennessee. There, engine man Frank Ofria applied his considerable expertise to the machining and assembly of the low-compression engine, hoping for an appreciable gain in output without compromising its street manners or ability to operate on fuel of the lowest grade, straight from the pump nozzle.

Block party

The foundation for the build began with a customer-supplied ’72 455 H.O. block, crank, rods, and heads, with instructions to transform it into a reliable yet powerful engine, willing to operate on 88 octane (or lower) and the ability to undertake a cross-country cruise without toting a load of octane booster. And just to keep things interesting, all this was to be accomplished with an eye towards the owner’s conservative budget.

A quick trip through the Summit online catalog allowed easy improvements with new hypereutectic pistons, upgraded rod bolts, and a street-oriented hydraulic flat-tappet cam, along with fresh lifters and pushrods. Since the original aluminum intake and Q-jet were not part of the delivered componentry, the induction package was upgraded to a current design aluminum intake and a vacuum-secondary carburetor.

Before commencing with the build, the block was validated with a Magnaflux test to ensure its structural integrity, then decked and squared to make sure that everything was dimensionally optimized. A previous .030-inch overbore was found to be out of spec, so the boring bar removed another .030-inch to clean things up, bringing total displacement to 469 cubic inches.

The bottom end remains largely stock since the block was fitted with four-bolt mains from the factory, and the rods were put back in service after correcting their factory center-to-center specs and outfitting them with ARP bolts. Pistons were also selected from the Summit site, with the choice going to a set of KB 371+.060-inch hypereutectic slugs that will serve quite adequately since the engine wasn’t intended for high-rpm, severe-usage duty.

Head games

Sealing the top of the cylinders to contain combustion is but one responsibility of the cylinder heads. They also contain the intake and exhaust ports as well as the valves that regulate the airflow in and out of the engine. The typical cylinder head contains more moving parts than any other major component of the engine.

With such a crucial role to play, it stands to reason that any attempt to improve the efficiency of a cylinder head has the potential to yield significant power gains.

Nominal combustion-chamber volume for the 455 H.O. head is 108 cc. This can be reduced incrementally through normal resurfacing of .020-inch, which also restores the flatness of the mating plane and provides a superior surface for gasket sealing. Both heads benefitted from a .025-inch cut.

Once the heads were deemed suitable for further improvements, the port bowls were opened up with a bit of hand porting before the heads were transferred to the Serdi seat- and valve-grinding machine for a precision three-angle valve job. The intake and exhaust ports were otherwise left untouched and considered adequate for this relatively mild street-oriented engine.

With the machine work accomplished, the heads were filled with stock-sized 2.11/1.77-inch (intake/exhaust) Ferrea stainless valves with undercut stems. Holding them in place is a set of Comp Cams valve springs, retainers, and locks, while pushrod guide plates enhance valvetrain stability.

Creating a cam-motion

Having a free-flowing set of heads won’t do you much good if the camshaft and related hardware aren’t capable and compatible. While a roller valvetrain would have certainly provided a significant step forward in terms of technology and reliability, the budgetary nature of the build precluded its inclusion. Instead, a hydraulic, flat-tappet cam was selected from the Comp Cams catalog, along with the appropriate lifters, pushrods, and springs.

There really are no significant shortcomings with the implementation of a flat-tappet cam; they’ve been used successfully for decades in millions of engines. And when installed properly and the recommended break-in procedure is followed, reliable operation can be expected for the life of the engine. After checking the cam specs with a degree wheel, it was installed straight up.

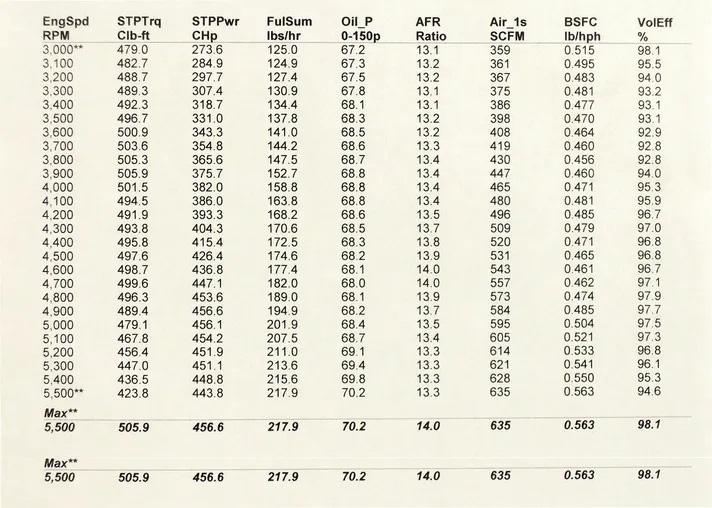

Keep in mind this was a low-budget, low-compression build, so we held no outrageous expectations. Still, the results were quite impressive, especially when considering the fundamental approach taken to gain power without losing tractability. Better yet, the lack of exotic internal hardware makes duplicating this pump-gas Pontiac well within the realm of reality, especially for those with a conservative budget. And, just to validate the 455’s parts selection and its pathway to power, we strapped it to the dyno. Take a look at the numbers:

Source: Chuck Hanson

Source: Chuck Hanson

Editor’s note: This article originally appeared on Hemmings Motor News.