AR glasses need far brighter displays than VR goggles, and displays made from arrays of miniaturised conventional III-V LEDs are a contender for this application. Multiple partnerships are racing towards this goal.

In this case, it will result in AR glasses designed by Kura, “based upon Kura’s proprietary architecture from the chip level up”, said Micledi, which incorporate Micledi’s microLED displays.

The Belgian company uses III/V materials, 3D integration and a proprietary asic to provide self-contained displays.

It commonly describes its displays as “300mm microled displays” because it is aiming to make them on 300mm wafers. However, it is currently making them on 200mm wafers, and has a deal, announced in May, for mass production at GlobalFoundries.

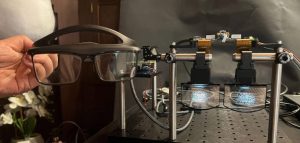

Kura AR glasses development kit

“Kura was one of the first customers to receive microleds from Micledi, said Micledi. “Under the partnership, Micledi will continue to provide Kura access to devices built in its 200mm fab, as well as provide Kura with early access to customised blue, green and red devices as they come from its 300mm wafer foundry.”

“We feel that Micledi is well-positioned to achieve leadership in 300mm microled fabrication, offering process advantages and direct compatibility with our custom 300mm backplane,” said Kura founder, CEO and CTO Kelly Peng.

Kura’s architecture is claimed to enable dynamic defect correction, and to tolerate defects and uniformity variation. It is aiming at 8K AR glasses “with microled panels that can be built now and in the next year, not several years from now”, it said. It also has a custom mixed-signal display driver IC and an arrangement to make it at TSMC.