For underbody battery protection, Rimline (=polyurethane) wet compression moulding material are low-viscosity liquid resins for low-pressure moulding of composites with a high fibre volume fraction – formulated for high-pressure mix machines.

Rimline FC (foam core) has flow properties designed for sandwich composites with complex 3d shapes, and to adhere to different over-moulding materials.

Rimline LFI (long fibre injection) is intended to be moulded into strong stiff sandwich parts with damage tolerance. As an example, with 30% glass fibre reinforcement, 1100kg/m3 can be achieved.

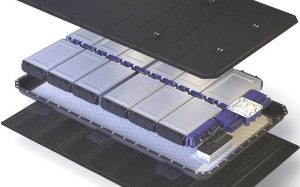

For battery enclosures, Araldite (=epoxy) FST (fire, smoke, toxicity) resins are available for flame-retardant composite parts. Araldite 3031-3032 wet compression moulding system is designed to provide “outstanding mechanical properties and stiffness”, according to the company. There are also Araldite sheet moulding compounds.

For battery top covers, Vitrox (=isocyanate polyurethane) wet compression moulding resin is aimed at composite lid structures that offer better thermal properties and lighter weight compared with metallic covers.

Inside the battery cell, Shokless encapsulation foam and elastomers are available for cell, module and pack-level potting foams and encapsulants – with variously-optimised thermal, vibration and structural properties.

Arathane thermally-conductive adhesives and encapsulants can both fix cells within a battery and contribute to heat management.

Inside the cells, Miralon (=includes carbon nanotubes) products are available to replace carbon black-based materials in some places, and metallic current collectors in others.

See these material at The Battery Show in Stuttgart (stand 8-A40m 23rd to 25th May), or follow this link.