July 05, 2022

From conveyor belts to drum mixers, motors are used in virtually every industrial application to drive machinery. Equipment downtime is the main motivation behind monitoring and maintaining plant equipment. When maintenance and repairs are necessary, it is imperative to be able to reliably control the machines for worker and technician safety. To properly address motor disconnect switch applications, Altech has devoted invaluable resources to ensure customers understand their needs and find successful solutions.

What are motor disconnect switches used for?

Motor disconnect switches break the path of each motor feed wire to rapidly open and close motor circuits when repair or maintenance is required. These switches can also be leveraged for lockout, or tagout, purposes to keep equipment shut down and isolated until the proper restart sequences are completed. Safety regulations require visible and local disconnect switches. As a result, a well-designed motor disconnect switch should enable effortless operation and a plainly visible switch handle that is easily operated through the panel.

Motor disconnect specifications ― What to look for

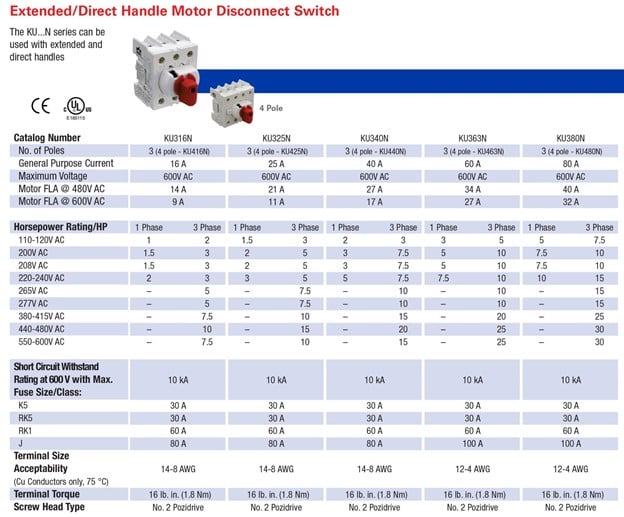

Understanding the motor disconnect switch’s major electrical parameters will help to ensure the right one is chosen for the application. These switches come with a general-purpose current and maximum voltage rating that specify both the rated amperage and voltage of the switch. National electrical code (NEC) safety regulations mandate local and visible motor disconnect switches to be placed within sight of the motor or device being served so that maintenance workers can see the position of the switch handle. To properly size the switch for the applicable motor, the NEC requires that the switch have ampere ratings greater than or equal to 115% of the motor’s full load amperes (FLA) or full load current rating. These ratings are listed on the nameplate of the motor. So, a motor’s FLA rating could be 21 A at 480 V AC and 11 A at 600 V AC. For this motor, a disconnect switch that has a rated voltage of 600 V AC and a general-purpose current of 25 A as well as a motor rating of 21 A at 480 V AC would be suitable. As shown in Figure 1, this should be listed out to be easily viewed in the motor disconnect’s datasheet to assist the user with properly selecting a motor disconnect switch.

NEC also maintains regulations on selecting a switch with a horsepower (HP) rating. For this, the equivalent locked-rotor current of the horsepower rating is at least 200% of the sum of the nonmotor loads, the three-phase, locked-rotor current of the largest motor, and the full-load current of all other three-phase motors operating at the same time. Motor disconnect switches with HP ratings from 1 HP up to 75 HP at 600 V AC will adequately power most of the common motor sizes.

Figure 1. Motor disconnect specification listing out which motor the disconnect switch is adequate for based upon the motor’s FLA and horsepower rating.

Figure 1. Motor disconnect specification listing out which motor the disconnect switch is adequate for based upon the motor’s FLA and horsepower rating.

Mounting a motor disconnect switch

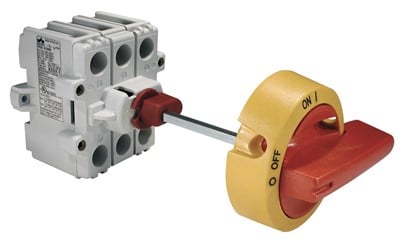

Mounting is a crucial part of selecting the right motor disconnect switch as some applications will have limited real estate to install and use the switch. Disconnect switches consist of wired contacts connected to an actuator such as a handle or a toggle. The actuator will ensure users can engage and disengage the electrical contacts without opening the distribution enclosure or motor controller. The extended/direct motor disconnect switches will generally come in two different mounting methods, as detailed below.

Figure 2. Exploded view of motor disconnect switch with shaft and handle. Source: Altech Corp.

Figure 2. Exploded view of motor disconnect switch with shaft and handle. Source: Altech Corp.

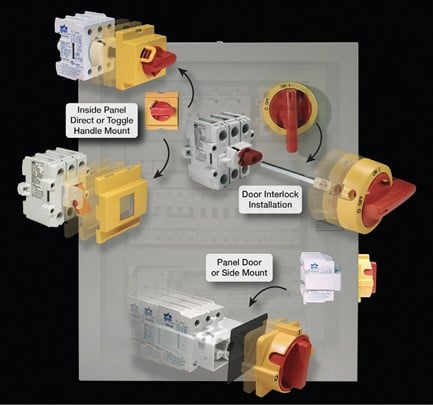

DIN rail mount with extended through-the-door handle

The DIN rail mount with an extended through-the-door handle leverages the motor disconnect switch itself as well as door interlock handle and door interlock shaft. For this installation, the motor disconnect switch is placed on the back panel and the door interlock shaft is inserted into the disconnect switch. This door interlock shaft, or extended rod, stays with the motor disconnect switch while the door interlock handle sits on the outside of the panel door (Figure 3). This allows the switch handle to be mounted on the outside of the panel while the switching and wiring are rail mounted.

Figure 3. Mounting example for inside panel application / direct handle mounting. Also shown on bottom left is a side mount extended handle example.

Figure 3. Mounting example for inside panel application / direct handle mounting. Also shown on bottom left is a side mount extended handle example.

Side/door mount handle

As shown in Figure 4, the side/door mounting kit allows users to mount the rotary switch on the side of the panel. This permits installations where multiple disconnect switches can be lined up vertically along the side of the panel to control various loads (e.g., pump, lighting, etc.) without opening the panel itself.

Figure 4. Different mounting options for motor disconnect switches. Source: Altech Corp.

Figure 4. Different mounting options for motor disconnect switches. Source: Altech Corp.

DIN rail mount with a direct handle

The DIN rail mount with a direct handle also allows the switch to be mounted directly to the DIN rail in the panel. The direct handle does not sit on a panel; Instead, the rotary handle is snapped to the face of the switch, covering the contacts and giving the user direct control of the motor disconnect switch (Figure 5).

Figure 5. UL 60947-4-1 (formerly UL 508) and UL 98 disconnect switches. Source: Altech Corp.

Figure 5. UL 60947-4-1 (formerly UL 508) and UL 98 disconnect switches. Source: Altech Corp.

Enclosures for motor disconnect switches

The enclosure of the motor disconnect switch protects the contacts from harsh environmental conditions such as dirt and moisture. Enclosures can be composed of polycarbonate, aluminum, sheet metal or stainless-steel enclosures with UL, NEMA and IP ratings for varying degrees of protection (Figure 6). A sheet metal enclosure will be resistant to moisture, UV and corrosion; however, a stainless-steel enclosure is superior for facilities where chemicals are consistently used for cleaning and maintenance such as breweries.

Figure 6. Left to right: Polycarbonate, aluminum, sheet metal and stainless-steel enclosures. Source: Altech Corp.

Figure 6. Left to right: Polycarbonate, aluminum, sheet metal and stainless-steel enclosures. Source: Altech Corp.

What to consider when choosing a switch

Available real-estate

A compact design could be essential when installing a motor disconnect switch where modern designs may not allow for much space. Smaller form-factor designs such as the UL60947-4-1A (formerly UL 508) may grant users more flexibility with one of the smallest 80 A switches in the industry.

A comprehensive range of accessories

It is crucial to choose a vendor with a wide breadth and depth in motor disconnect switches as well as accessories such as fuse holders, toggle handles, door interlock handles and enclosures. These are all factors that contribute to the success of the installation and operation of the equipment. These accessories should also be able to work with the different types of motor disconnect switches offered so there is a level of simplicity in selecting the right kits and accessories.

Certifications

As with any industrial application, safety and certifications are often mandatory and should therefore be heavily considered when selecting a motor disconnect switch. Altech disconnect switches have been designed and manufactured in accordance with EN 60947-l, EN 60947-3, IEC 60947-1, IEC 60947-3, Low Voltage Directive 2006/95/EY and UL60947-4-1 (formerly UL508).

Altech Corp

Motor disconnect switches are an essential part of any industrial installation that leverages motors. It is critical to understand the specifications, types of switches and mounting options available to successfully install and operate these devices. Altech Corp offers an array of open and enclosed motor disconnect switches and general-purpose current ratings. The selection comes with several available auxiliary components and mounting kits for better installation and industrial regulatory compliance. Altech Corp’s legacy and expertise in industrial installations makes them an ideal partner and supplier for motor disconnect switches. For more information, visit altechcorp.com.