June 21, 2023

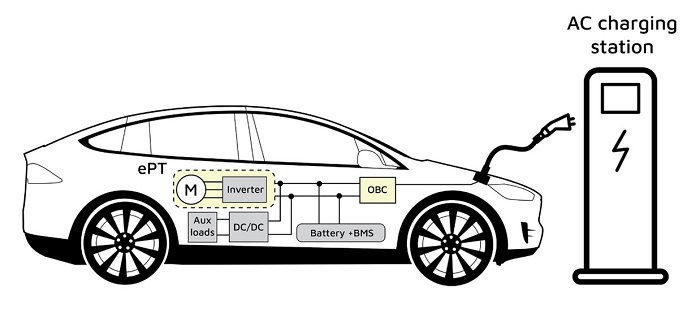

Communication and control systems play a crucial role in electric vehicles (EVs) by enabling key functions like battery management, charging and communication between components and external systems. Together these systems work in concert to ensure that the EV operates safely and efficiently.

Figure 1. Selecting robust and reliable control and communications system hardware is critical to ensuring the performance and safety of EVs. Source: Harwin

Figure 1. Selecting robust and reliable control and communications system hardware is critical to ensuring the performance and safety of EVs. Source: Harwin

There are several steps vehicle manufacturers can take to increase the reliability of EV communication and control systems, starting with the selection of robust and proven connectors, wiring assemblies, shielding and contacts. Although these are often given less priority than larger, more expensive items, such as the motor, battery pack or controllers, their failure can result in consequences that have significant cost and safety implications – like sub-optimal power usage, overheating of batteries, charging problems, to name a few. The role communication and control systems play in the overall performance of EVs is just as important to keep top of mind, as well as factors for manufacturers to consider when selecting hardware.

Communication and control systems

The communication network is responsible for allowing the various components of the EV to talk with each other. Some of its key functions include (but are not limited to):

- Charging management: This enables the vehicle to communicate with charging infrastructure and ensures protection of the motor controller. It also receives real-time data from the battery management system (BMS) to adjust the motor performance accordingly.

- BMS: The BMS monitors the battery’s voltage and current so that charging and discharging occur safely. Issues with the BMS can lead to serious safety concerns, such as overheating of batteries, which degrades performance and increases the potential for a thermal runaway event.

- Safety system operation: The communication system allows the vehicle’s advanced driver assistance systems to receive real-time data from sensors and cameras for collision avoidance and lane departure warning.

Figure 2. EV Control systems play a critical role in regulating the various aspects of the vehicles operation. Source: Harwin

Figure 2. EV Control systems play a critical role in regulating the various aspects of the vehicles operation. Source: Harwin

Control systems use the communications network to manage and regulate various aspects of the vehicle’s operation. This includes monitoring and controlling power distribution and battery temperature, which can impact the vehicle’s range and energy losses. It is also responsible for managing the performance of various subsystems like suspension, regenerative braking, powertrain, motor and stability control.

System operation and hardware selection

As EV safety, performance and efficiency are predicated on secure and robust communication between the different components of the vehicle, utilizing well-established protocols, like controller area network (CAN) or Ethernet is critical. So too is the use of robust hardware that can withstand harsh conditions, such as high temperatures and vibrations.

Harwin offers a wide range of connectors and hardware to meet the demanding requirements of automotive and industrial applications, including the following.

HRi

HRi interconnect solutions have a proven track record in automotive, aerospace and defense applications and are designed for performance and reliability in extreme environments. The range features Gecko connectors, which provide a low profile, dual-row interconnect solution, ideally suited for stacking and cable mating in areas where PCB real estate is at a premium. Datamate (M80 and M83 series) connectors provide a flexible interconnect solution and are available in single-, double- and triple-row configurations.

EZi

Designed for easy assembly, the EZi portfolio features board-level shielding solutions and associated accessories that can help EV manufacturers simplify production processes. Notable products include the popular EMI/RFI shielding cans, simple-to-adapt shielding kits, cable clips and jumper links.

BBi

The BBi range comprises highly durable board-to-board connectors for industrial and embedded applications. The connectors are designed for ease of integration and can help manufacturers address acute space constraints. Common applications include motor controllers, which require high-current, high-speed and low-loss connections.

Figure 3. Harwin offers a wide range of hardware and interconnect solutions to meet the demanding requirements of EV manufacturers. Source: Harwin

Figure 3. Harwin offers a wide range of hardware and interconnect solutions to meet the demanding requirements of EV manufacturers. Source: Harwin

Harwin

More than 10 million EVs were sold worldwide in 2022, according to the International Energy Agency (IEA). Sales are expected to grow by another 35% this year to reach 14 million. Overall, the share of EVs in the global auto market has risen from around 4% in 2020 to 14% in 2022 and is set to increase further to 18% this year.

Ensuring the efficiency and reliability of EVs will be essential to their continued adoption. Communication and control systems play a crucial role in managing and regulating various aspects of the vehicle’s operation. To this end, manufacturers must prioritize the use of high-quality, robust components, including interconnects and wiring systems.

Harwin is a leading provider of connectors, wiring assemblies and other interconnect solutions for the automotive industry. The company has a long history of innovation in the EV market, along with other demanding industries such as aerospace, defense and medical devices. More information on Harwin’s hardware solutions for EVs can be found here.