Figure 1: Fast, reliable, and safe battery chargers are an essential element to accelerate the adoption of electric vehicles. Source: Boyd

Figure 1: Fast, reliable, and safe battery chargers are an essential element to accelerate the adoption of electric vehicles. Source: Boyd

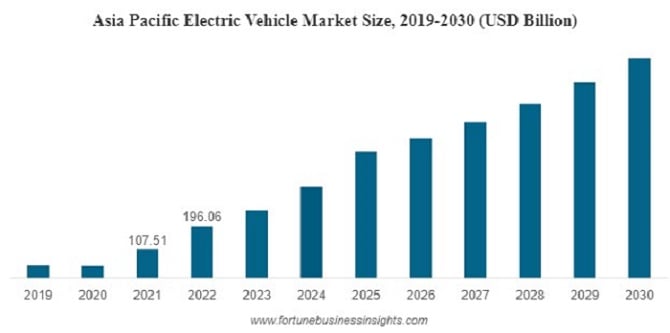

Fast, reliable and safe battery chargers are an essential element to accelerate the adoption of electric vehicles (EVs). Advancements in EV battery technologies are driving the development of high-performance, sustainable and environmentally friendly transportation ecosystems. According to Fortune Business Insights, the global EV market value is expected to reach almost $1.5 trillion by 2030, growing at a 17.8% compound annual growth rate (CAGR) from 2023 to 2030. Effective EV battery charging infrastructure is a requirement to realize this growth.

Figure 2: Asia Pacific EV market size. Source Fortune Business Insights.

Figure 2: Asia Pacific EV market size. Source Fortune Business Insights.

EV battery charger types and hardware

The diverse EV battery charger types such as Level 1 charging (120 V AC), Level 2 charging (240 V AC) and superchargers (400 V DC to 800 V DC) are tailored for specific purposes.

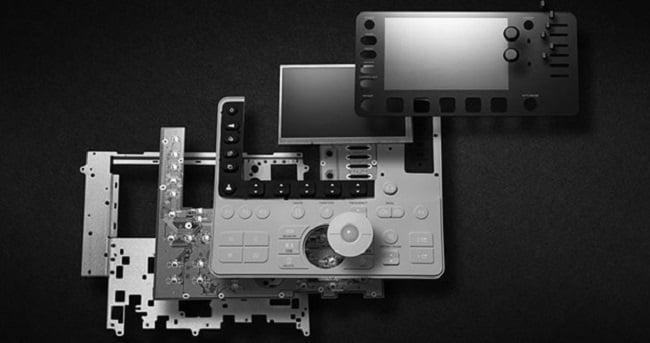

Figure 3: Boyd Trusted Innovation. Source: Boyd

Figure 3: Boyd Trusted Innovation. Source: Boyd

Level 1 charger

Level 1 chargers consist of a cable, connector, control unit and essential safety features operating at 120 V AC and drawing relatively low power, around 1.44 kW. They offer the slowest charging option and are convenient for overnight charging at home, requiring an extended time to fully charge an EV.

Level 2 charger

Level 2 chargers are equipped with a cable and connector, control unit, display, and enhanced safety features including ground fault protection and temperature monitoring. These chargers operate at 240 V AC and offer variable charging speeds, typically ranging from 3.3 kW to 19.2 kW or higher, depending on their capacity. They are commonly deployed in public charging stations, workplaces and residential installations, offering shorter charging times compared to Level 1 chargers.

Level 3 charger

Level 3 chargers, or superchargers, feature high-capacity components, a liquid cooling system, a charging cable, an advanced control unit, a display and a payment terminal. These chargers deliver direct current to the EV battery with power consumption ranging from 50 kW to 350 kW or even higher, enabling shorter charging times when compared to other charging types for the same model.

EV battery charger: Challenges

As EV charger technology advances, the EV charging landscape confronts a range of challenges encompassing charging infrastructure, charging speed, compatibility, energy supply, costs, range anxiety and battery degradation. For instance, superchargers generate excessive heat due to the high current passing through relatively small-diameter cables and poses a risk for safe and reliable battery operation. Therefore, effective thermal management is a critical aspect of EV charging station performance, reliability, and safety.

Boyd’s innovative solutions for EV battery charging

Thermal management

Boyd’s cutting-edge cooling technologies effectively dissipate heat and prevent thermal runaway without introducing excessive weight or size. Harness Boyd’s extensive knowledge in air-cooling technologies, airflow management, and design and manufacturing to fine-tune cooling performance, ensure secure and reliable charger cable operation, extend charger lifespan, and improve overall performance. Boyd’s liquid cooling systems and customized cold plate applications effectively manage the substantial heat generated as a byproduct of crucial eMobility inverters and other power electronics, enabling the highest level of power conversion efficiency, extended range and faster charge cycles to improve consumer adoption.

Figure 4: Boyd’s cutting-edge cooling technologies effectively dissipate heat and prevent thermal runaway. Source: Boyd

Figure 4: Boyd’s cutting-edge cooling technologies effectively dissipate heat and prevent thermal runaway. Source: Boyd

Figure 5: Boyd’s offerings include optically clear adhesives, polarizers, anti-glare films, light control films, brightness enhancing films, reflective films and light diffusing films. Source: Boyd

Figure 5: Boyd’s offerings include optically clear adhesives, polarizers, anti-glare films, light control films, brightness enhancing films, reflective films and light diffusing films. Source: Boyd

Display and HMI

Elevate the quality and functionality of displays with Boyd’s premium components, expertly engineered and manufactured to withstand the tough environmental and consumer use factors for charging stations. Boyd’s offerings include optically clear adhesives, polarizers, anti-glare films, light control films, brightness enhancing films, reflective films and light diffusing films. They also provide durable nameplates and branding solutions crafted from a versatile selection of materials, including aluminum, stainless steel, acrylic, polyester and polycarbonate. Enhance customer experience in outdoor environments without increasing weight or power consumption using Boyd’s robust switch interfaces designed for optimal performance.

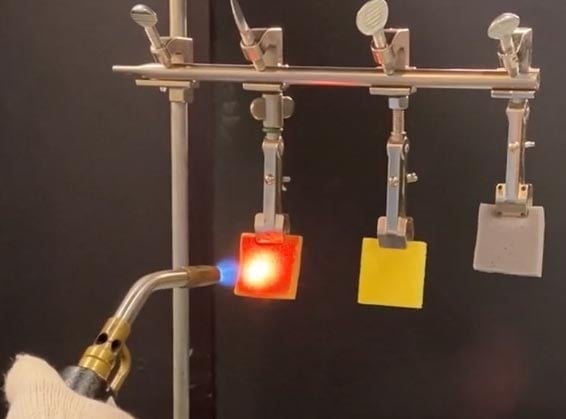

Insulation and shielding

Optimize the performance of EV chargers while safeguarding against electromagnetic interference (EMI), radio frequency interference (RFI) and challenging environmental conditions with Boyd’s EMI shielding materials, such as foil tapes, fabric over foam and conductive tapes, foams, and elastomers. Boyd’s range of thermal and electrical insulators, including SOLIMIDE, polyimide, polycarbonate and polypropylene UL 94-rated insulating films help maintain an ideal thermal operating range in extreme temperatures and provide protection against flame and spark voltages.

Figure 6: Boyd’s range of thermal and electrical insulators help maintain an ideal thermal operating range in extreme temperatures and provide protection against flame and spark voltages. Source: Boyd

Figure 6: Boyd’s range of thermal and electrical insulators help maintain an ideal thermal operating range in extreme temperatures and provide protection against flame and spark voltages. Source: Boyd

Figure 7: The company collaborates with flexible adhesives like very high bond tapes, double-coated tapes, transfer tapes and other materials. Source: Boyd

Figure 7: The company collaborates with flexible adhesives like very high bond tapes, double-coated tapes, transfer tapes and other materials. Source: Boyd

Environmental sealing and protection

Boyd’s comprehensive range of sealing and gasketing solutions utilizes materials such as silicone foams, closed-cell silicone sponges, polyurethane foam, EVA, vinyl, neoprene and thermoplastics. The company collaborates with flexible adhesives like very high bond tapes, double-coated tapes, transfer tapes and other materials to efficiently and robustly assemble ingress seals to waterproof charging stations.

Innovate with Boyd

Boyd has decades of experience and expertise delivering thermal solutions for the power management industry and a track record of shipping over one billion eMobility components worldwide. Leverage their liquid cooling and material science heritage to incorporate multiple capabilities into vertically integrated eMobility solutions.

Boyd has decades of experience and expertise delivering thermal solutions for the power management industry and a track record of shipping over one billion eMobility components worldwide. Leverage their liquid cooling and material science heritage to incorporate multiple capabilities into vertically integrated eMobility solutions.

Whether those needs involve safeguarding and cooling EV batteries, enhancing brand identity, or protecting and cooling advanced superchargers, Boyd empowers customers to innovate and accelerate their time to market. To learn more about Boyd’s EV battery charger solutions or to discuss a project’s needs, schedule a consultation with Boyd’s experts.