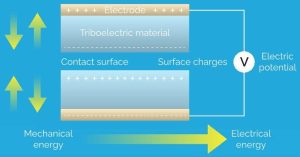

Triboelectric generators produce power through electrostatic induction when dissimilar insulating materials are brought together and parted (right, and far below).

Two of the things that push back against more efficient triboelectic generators, according to the Gwangju research team, are wasteful charge recombination with the rear (energy extraction) electrodes, and charge accumulation leading to charge repulsion on the front surfaces of the materials when they are pre-charged in manufacture.

“In the design of high-performance TENGs, it is critical to transport the charge on the surface to a deep position while reducing charge recombination,” said Professor Chanho Pak.

What was needed was mechanism to pull charge from the front surface into the body of the triboelectric material, and a way to stopped this charge getting all the way to the rear electrode.

The triboelectric materials are chosen for their ability to naturally hold a high positive or negative charge when presented with a high field during manufacture

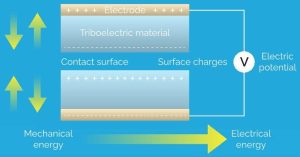

A gradient of charge-confinement was the answer to both issues, created by layers of carbon nanospheres with different surface areas (diagram left). “The layers transport as well as confine the charges,” said Pak.

Each of the two facing materials has a copper back electrode, then a layer of polymer with 300nm diameter spheres with an extraordinary high surface area, 120m2/g, to strongly confine charge and prevent carriers from reaching the electrode.

The gradient comes from the two subsequent layers, of 40m2/g (700nm) spheres then 20m2/g (1μm) spheres, finally topped by the triboelectric front surface.

To get opposing potentials, one of the structures has a Nylon 11 front face and its carbon spheres are held in a Nylon 11 matrix. For the other, the front face is PTFE and the spheres are held in a polyvinylidene matrix.

“As a result of this gradient arrangement, the injected charges [during manufacture pre-charge] could drift towards the electrode but were confined just before reaching it,” according to the Institute. “With the addition of charge-confining layers, the researchers improved the output voltage and current of the TENG by 40 [15.2V to 600V] and seven times, respectively.”

The work is covered in ‘Controllable triboelectric series using gradient positive and negative charge-confinement layer with different particle sizes of mesoporous carbon materials‘ published in the journal Small Methods

How they work

There is no transfer of electron between the surfaces of triboelectric generators. Instead, charges shift within the materials as they approach, and recede in a way that can drive an ac current in an external circuit. External power levels are generally in the microwatt range.

The insulating materials are pre-charged in manufacture – one positive (nylon in the Gwangju case) and one negative (PTFE/PVD). In the research, with triple-layer carbon loading they could hold up to 600V of potential difference, but only 15V without the carbon gradients.

Taking the Nylon-copper combination in isolation, the high positive charge within the Nylon will pull electrons into the copper if there is any external path through which the electrons can arrive. The opposite is true for the PTFE-PVD-copper combination in isolation, whose negative charge will push electrons out of its backing copper.

If the two copper backing layers are connected, one can be the source of electrons for the other.

Now if the PTFE and Nylon faces are pushed together [oh, dear reader, for time to draw a diagram], much of their high electric fields will be temporarily be neutralised by one another, leaving little or no field to hold charge in the copper layers, which means the surfeit of electrons in the copper behind the nylon side will rush back into the copper behind the PTFE/PVD.

When the material are once again pulled apart, the copper electrodes once again feel their local fields, and the electrons rush forth once more.

It is this back and forth flow of electrons between the copper electrodes that can be exploited in an external circuit.