Researchers at IBM and ASMPT have developed a new way to bond chiplets that fuses copper and an oxide in layers that are just a few atoms thick using no solder.

The result is a bond between chiplets that’s only around 0.8 microns, compared to the 150-30 microns being achieved by solder, or a combination of solder and copper, sitting on top of a metal pad.

It has implications for integrating chiplet technology into smaller devices, for example, and increasing the performance of chiplets, or their energy efficiency.

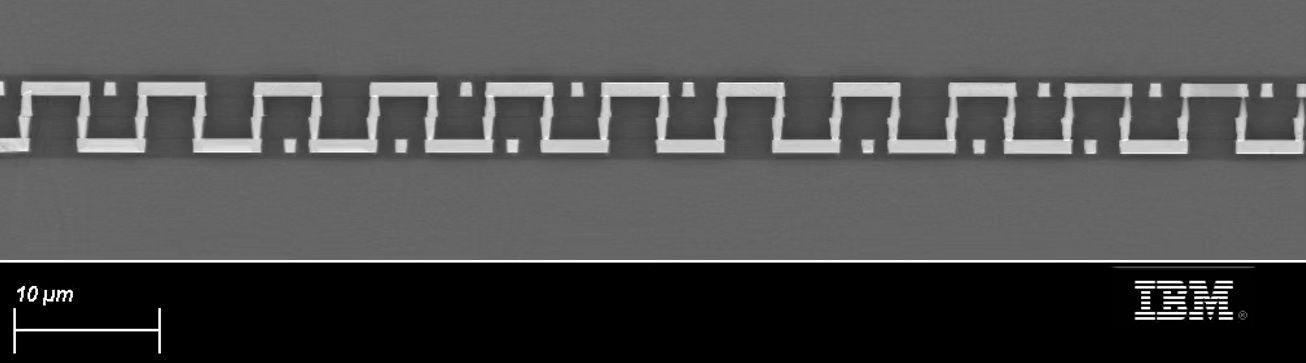

A A microscopic image of what the minuscule bonding between two layers with the team’s method looks like.

A A microscopic image of what the minuscule bonding between two layers with the team’s method looks like.

In the team’s method, the toughest challenge was to ensure that the bonding was secure, removing potential moisture or air bubbles on a minuscule scale. Just three molecules of water between the bonding layers would be enough to break the connection between layers.

Removing this hazard, along with air bubbles, while maintaining clean surfaces for the layers that are bonding together — and ensuring that this process could be reliably carried out again and again — were the main challenges the team sought to overcome in their research.