“9179-000 Series IDC Splice Connectors are packed with features designed to make them an attractive alternative to traditional splicing,” according to the company. “They establish cold-welded, gas-tight connections and have been proven to withstand common levels of shock, vibration and temperature cycling. The series is also compatible with potting processes.” – IDC (insulation displacement connection) means that it is not even necessary to strip away insulation.

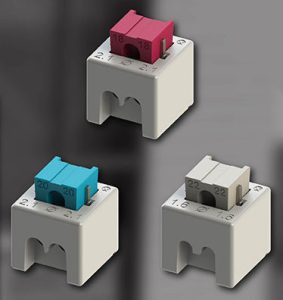

They accept two solid and stranded (up to 19 strand) wires, that will be electrically connected once the splice is operated – after which the connector will measure 8 x 7.8 x 7.2mm. Parallel-jaw pliers are one suggested operating tool.

Wires can be inserted from one or both sides, and various wire gauges from 24 to 14AWG are supported.

However, this is where they get a bit fussy as each hole only supports one size of wire: 24, 22, 20 or 18AWG. The associated insulation hole diameter is 1.6 or 2.1mm. The connectors either have two equal holes, or two different sizes – 10 devices in total cover most combinations.

Conductor and insulation sizes are marked on every hole, and the operating knobs are colour coded.

Operation is up to 300Vrms (or equiv dc), across -40 to +125°C, and up to 7A (24 and 22AWG), 10A (20AWG) or 13A (18AWG).

Materials are UL94 V-0 glass-filled thermoplastic and Pb-free, tin-over-nickel-plated phosphor bronze.

Sadly missing from the 9179-000 data sheet are any numbers to back-up the shock, vibration and temperature cycling claims. Also find the parts on this product page.

Applications are foreseen in industry, lighting, consumer, automotive, oil and gas.