Figure 1. The increase in AI information also increases transmission and feedback time, leading developers to focus their efforts on offering more efficient information transmission devices. Source: Shiu Li Technology

Figure 1. The increase in AI information also increases transmission and feedback time, leading developers to focus their efforts on offering more efficient information transmission devices. Source: Shiu Li Technology

With the development of artificial intelligence (AI) computing comes the inherent need to further evolve 3C products — computer, communication and consumer. AI servers, 5G micro base stations, Wi-Fi 7 network routers, AI computers, AI smartphones and more are all facing the challenges of a new generation. As the core processors compute faster, the amount of waste heat generated during the operation of electronic products increases; addressing this waste heat problem is crucial to network reliability.

The mechanics of waste heat

Early air-cooled fans use air as a medium. Heat interface materials, vapor chambers (VC) or heat pipes are used as intermediate materials, dissipating heat through convection between heat sinks or fans and air.

Liquid cooling can be divided into two types: All in one (AIO) integrated water cooling and immersion cooling. Among them, immersion cooling systems are most suitable for high-density servers. They immerse the servers in non-conductive electronic engineering fluid, directly transferring waste heat to the liquid without the need for heat sinks and fans. This method offers the best heat dissipation, but it is expensive, making it less affordable for general consumers in terms of equipment costs and maintenance fees.

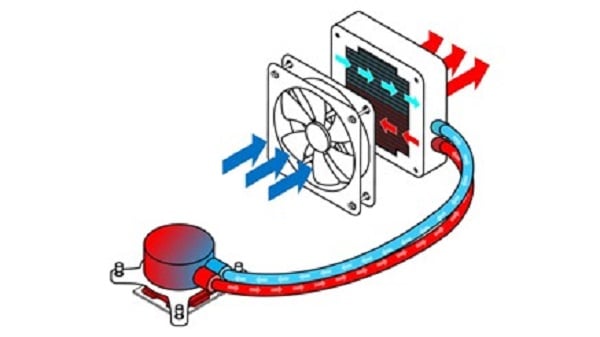

Figure 2. AIO liquid cooling concept. Source: Intel

Figure 2. AIO liquid cooling concept. Source: Intel

Consumer-oriented AIO water cooling systems are increasingly favored for their high cost-performance ratio (CP value). In these systems, the heat dissipation mechanism involves transferring heat from the heat source through thermal interface materials (TIMs), cold-side heads, cold plate heat sinks, fans and air convection. A micro motor is employed to circulate the fluid carrying heat from the cold-side head in contact with the heat source back to the cold plate for cooling.

In this setup, the TIMs play a crucial role by filling tiny gaps between the cold-side head and the heat source surface, thereby increasing the contact surface area and improving heat transfer. Therefore, high thermal conductivity and low thermal impedance coefficient materials are essential indicators.

Superior TIMs for the job

LiPOLY’s TT3000 thermal paste exhibits excellent fillability and ensures perfect attachment between the AIO cold-side head and the heat source chip. It boasts an ultra-low thermal impedance coefficient of 0.007 (°C-in²/W), resulting in exceptional heat transfer.

Similarly, the non-silicon thermal paste G3380NT offers an ultra-low thermal impedance coefficient of 0.01 (°C-in²/W). Currently, AIO cooler CPUs and GPUs are suitable for ultra-low thermal resistance thermal pastes, while AIO cooler SSDs are suitable for high thermal conductivity coefficient pads. LiPOLY’s N800C and T-work9000 pads have thermal conductivity coefficients of 17~20 (W/mK) and offer excellent performance in chip protection and heat dissipation due to their buffering shock resistance and high compressibility.

5G wireless network communication and Wi-Fi 7 devices play the role of AI information transmitters. As the amount of AI information increases, the transmission and feedback time will be longer. This has led developers to focus their efforts on offering more efficient information transmission devices. Wi-Fi 7 routers have a maximum transmission speed of 46 Gbps, which is 4.8 times that of Wi-Fi 6. This indicates that the higher the power consumption in multi-band high-efficiency wireless transmission, the more waste heat is generated.

Early network communication devices were unable to effectively dissipate heat, resulting in slower data processing speeds and shorter device lifespans. LiPOLY’s high thermal conductivity pad material is the only choice to solve heat-related failures in Wi-Fi 7 devices. Moreover, in wireless communication, high-frequency electromagnetic interference (EMI) accumulates electromagnetic waves in the form of heat. Therefore, TIMs are increasingly required to have the ability to absorb EMI, leading to the development of thermal absorption interface materials.

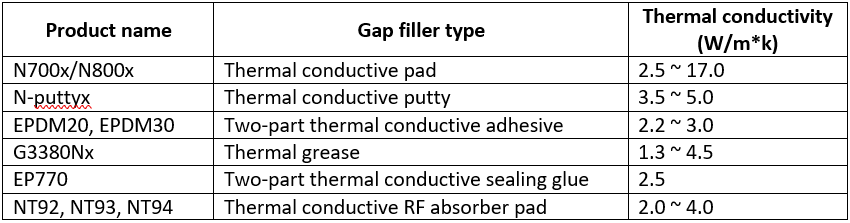

LiPOLY’s thermal absorption pad materials in the TEM96 series, non-silicone gel thermal absorption pad materials NT92, NT93 and NT94, possess the advantages of thermal conduction and electromagnetic wave EMI absorption, making them suitable for electromagnetic wave interference applications. They also address issues such as heat generation after absorbing electromagnetic waves.

Besides addressing heat dissipation issues in fiber optic fixed network equipment (e.g., routers, SFPs), TIMs are required to have a low amount of low molecular weight (LMW) siloxanes and cannot release organic silicon volatiles. Contamination of LMW siloxanes can lead to two serious conditions: First, over time, slowly released LMW siloxanes can form a layer of silicon dioxide on the surface of optical lenses and fiber transmission junctions, affecting light transmission. Alternatively, migration of organic silicon LMW siloxanes can contaminate the surfaces of board card gold finger junctions, contact switches and conductive layers of buttons; this forms an insulating layer of silicon dioxide that causes electronic transmission failure. Because of this, LiPOLY’s non-silicone gel TIMs are the optimal choice.

Oil exudation is common in silicone gel products, and the exuded small molecules contain D4, D5 and D6; these are persistent, bio-accumulative, toxic (PBT), highly persistent and highly bio-accumulative (vPvB). In June 2018, they were included in the SVHC list of highly concerning substances. It can be concluded that the use of D4, D5 and D6 may cause serious harm to human health and the environment, thus the EU considers it necessary to take action to restrict their use. Non-silicone gel TIMs, on the other hand, are environmentally friendly and free from low siloxane pollution to both organisms and the environment. ESG environmentally friendly materials will become the future development trend.

In addition to a wide range of silicone-based TIMs, LiPOLY is also an industry leader for environmentally friendly non-silicone TIMs. These materials can meet various application requirements of different customers.

LiPOLY by Shiu Li Technology

Shiu Li Technology is a world-leading thermal management manufacturer, developing high-performance thermal solutions for product designers around the globe. Selling under its brand LiPOLY, Shiu Li Technology has heavily invested in the development of advanced thermal conductive products for high powered modules. In 2018, Shiu Li Technology was established in the U.S. to better serve customers in North America and Europe.

Shiu Li Technology has served customers worldwide, delivering thermal solutions in computer manufacturing, data communication, consumer electronics, data centers, military equipment, automotive equipment, lighting, power conversion and more. Contact the experts in thermal management solutions to learn more.