Towards optimising such structures, researchers at Pusan National University in Korea have found a way to make a monolithic pre-object flat-pack by defining stiff flat parts and flexible hinges in stacked sheets of carbon fibre and aramid cloth.

“Its applications include joints to create a Transformer-like robot, solar panels and solar sails for spacecraft, or a foldable and rollable electronics substrate,” said research engineer Dong Gi Seong.

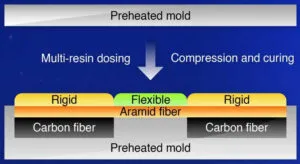

The technique uses multi-resin disposition – squeezing an epoxy resin that cures onto ridged polymer into the cloth stack where stiffness is needed (KFR-120V with KFH-163 hardener), and modified epoxies that cure into elastomers where hinges are needed (YD 171 plus UME 330 with G 640 hardener).

After curing, “these composites exhibit a flexural modulus of 6.95GPa in rigid sections and 0.66GPa in foldable sections, with a bending radius of less than 0.5mm, ensuring both flexibility and stability under repetitive cycles with high strain tolerance”, said the university. “Furthermore, the fabricated structure is lightweight, mechanically robust, and capable of complex motions such as extension, compression, bending, twisting and deployment.”

The work is described in ‘Deployable fiber-reinforced polymer for advanced monolithic rigid-soft robotics applications‘ published in Composites Part B: Engineering.