There are 512 x 320 individually addressable mirrors, each 48μm across.

Fraunhofer IPMS is handling commercialisation, and said that the mirrors enable “the redirection of light beams or the generation and control of 2D intensity profiles and patterns with variable intensity. Because light is redistributed rather than masked, a high light yield is possible.”

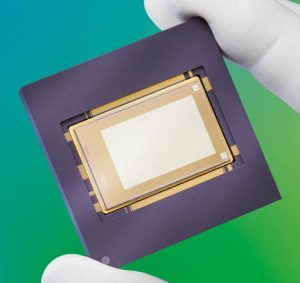

This part of Fraunhofer, Institute for Photonic Microsystems, develops micro-mirror-based spatial light modulators (left) with multiple millions of reflectors and makes them on 200mm wafers.

They are used in deep UV lithography, PCB manufacturing, semiconductor inspection, metrology, adaptive optics, astronomy, holography and microscopy.

It has its own ISO 9001 certified laboratories and a 1,500m2 clean room.

“In addition, Fraunhofer IPMS develops the electronics and software to drive the devices,” it said. “To facilitate the technology transfer into application, the institute offers evaluation kits to its customers. The set-up includes not only the micro mirror chip itself but also the complete control electronics including software.”

Building on the mirror arrays, it is developing the rest of the technology required for computer-generated holography, saying: “The first application scenario is a head-up display for automobiles.”

Building on the mirror arrays, it is developing the rest of the technology required for computer-generated holography, saying: “The first application scenario is a head-up display for automobiles.”