S. Himmelstein | June 12, 2023

Source: Joule (2023). DOI: 10.1016/j.joule.2023.04.006

Source: Joule (2023). DOI: 10.1016/j.joule.2023.04.006

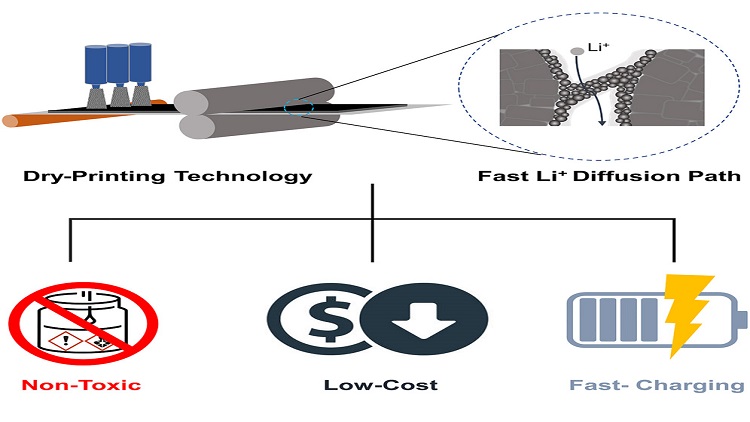

The use of flammable and toxic solvents in lithium-ion battery electrode production can be eliminated with a new solvent-free dry-printing manufacturing process. The technology also consumes less energy and incurs lower economic investment relative to available routes for fast-charging electrode production.

According to researchers from Worcester Polytechnic Institute, Texas A&M University, Rice University, Microvast Inc (Florida), U.S. Argonne National Laboratory and U.S. Brookhaven National Laboratory, the solvent-free scheme yields electrodes that charge to 78% of capacity in 20 minutes and eliminates use of solvents, slurries and long production times.

Battery electrode manufacturing currently relies on combining active materials, conductive additives, polymers and organic solvents to create a slurry that is pasted onto a metal substrate, and oven dried. The more sustainable system described in Joule instead combines dry powders that are electrically charged so they adhere when sprayed onto a metal substrate. Dry-coated electrodes are heated and compressed in a roll-to-roll system, eliminating the conventional drying and solvent-recovery process.

The dry-printing method is estimated to cut battery manufacturing energy use by 47% in the production of components that exhibit better performance than the commercial standard slurry-cast electrodes.