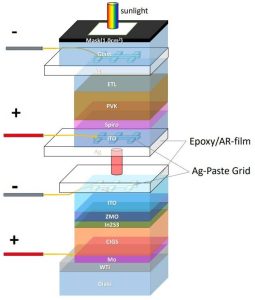

Midsummer makes CIGS (copper indium gallium selenide) solar cells, and it collaborated with University of California, Los Angeles and Pioneer Materials to stack a perovskite cell on top of one of its products to make the tandem cell – with the wide-bandgap perovskite designed to absorb and converting the shorter wavelengths that the now underlying CIGS cell cannot make use of.

This is a four-terminal cell, with mid-stack electrodes that allow the two sub-cells to operate at different currents – which gets the best out of tandem cells.

“Our ultimate goal is to demonstrate two-terminal perovskite-CIGS tandem cells, suitable for mass production,” according to Professor Yang Yang, whose lab provided the UCLA end of the project.

“We feel fortunate to be working with Professor Yang’s group at UCLA, which has demonstrated key advances in perovskites,” said Leon Chiu, president of Pioneer Materials, which supplies compound sputtering targets to Midsummer for CIGS cell manufacture.

Midsummer makes solar roofs using flexible CIGS solar cells made in-house on stainless steel substrates.

Its production process takes place in a custom 25-chamber vacuum machine (left) that makes cells on 156 x 156mm stainless steel substrates. Each machine completes a solar cell every 20s. It “deposits all thin-film solar cells layers in an unbroken vacuum chain”, said the company. “As the cell does not leave the vacuum environment between the stages of the process, the risk of contamination and thus also the requirements for the surrounding clean room are minimised.”

Its production process takes place in a custom 25-chamber vacuum machine (left) that makes cells on 156 x 156mm stainless steel substrates. Each machine completes a solar cell every 20s. It “deposits all thin-film solar cells layers in an unbroken vacuum chain”, said the company. “As the cell does not leave the vacuum environment between the stages of the process, the risk of contamination and thus also the requirements for the surrounding clean room are minimised.”

Each solar cell has a unique ID, against with production tracing data is stored for continuous quality control. “This is an advantage in research, where all deviations in a process can be traced to cell level,” it said.