S. Himmelstein | July 15, 2022

A new type of prosthetic using microfluidics-enabled soft robotics has been engineered by Canadian researchers to greatly reduce skin ulcerations and pain in patients who have had an amputation between the ankle and knee.

Most lower-limb amputations are the result of diabetic foot ulcers, and the lower limb typically swells at unpredictable times, resulting in volume changes of 10% or more. The prosthesis commonly used after amputation includes fabric and silicone liners that can be added or removed to improve fit. The amputee must manually change the liners, but neuropathy leading to poor sensation makes this difficult and can inflict more damage to the remaining limb.

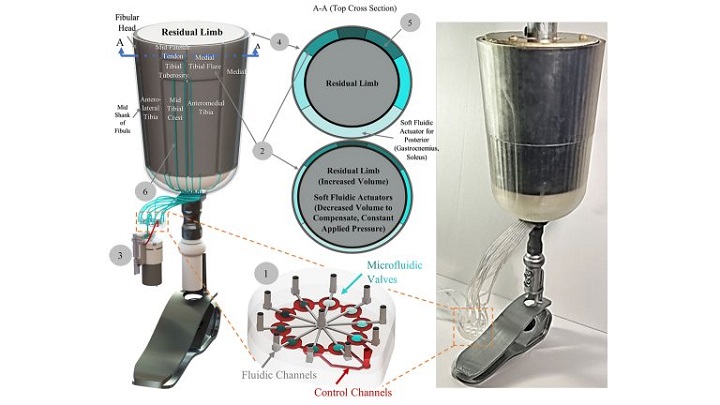

The researchers sought to address this problem by replacing the silicon/fabric limb liner with a single liner and integrated soft fluidic actuators as an interfacing layer. The actuators can be inflated to varying pressures based on the anatomy of the residual limb to reduce pain and prevent pressure ulcerations.

A microfluidic chip with 10 integrated pneumatic valves was developed to control each actuator. The system is controlled by a miniature air pump and two solenoid valves that provide air to the microfluidic chip. The control mechanism is small and light enough to be worn as part of the prosthesis.

Proof-of-concept rendering (left) and photo (right) of the prototype microfluidics-enabled prosthesis. Source: University of Waterloo

Proof-of-concept rendering (left) and photo (right) of the prototype microfluidics-enabled prosthesis. Source: University of Waterloo

Extensive measurements of the contact pressure provided by each actuator were compared to the desired pressure for a working prosthesis, confirming that all 10 actuators produce pressures in the desired range.

The University of Waterloo (Canada), Myant Inc. (Canada), Grand River Hospital (Canada) and Prosthetic Ability (Canada) scientists plan additional research to integrate pressure sensors directly into the prosthetic liner and to test newly available knitted soft fabric that incorporates pressure sensing material.

The research is published in Biomicrofluidics.