Infrared (IR) cameras contain detectors, known as focal plane arrays (FPAs), that detect and measure thermal energy – or heat. The infrared thermal energy is converted into electronic images that indicate differences in surface temperature among the objects being imaged. The FPAs must be cooled to cryogenic temperatures by special coolers, known as dewars to reduce background noise and increase camera sensitivity, resolution, optical efficiency and operational range. These dewars are installed within the cameras and maintain a consistent cryogenic cooling temperature under a wide range of operating and environmental conditions.

There are special challenges that must be considered when designing, fabricating and assembling integrated dewar systems in difficult applications, such as military aircraft, missiles and space surveillance. Qnnect (pronounced: “Connect”), a worldwide developer and supplier of hermetic electronic assemblies, offers the full range of capabilities to develop custom integrated dewar assemblies for the most demanding environments.

Dewar design requirements

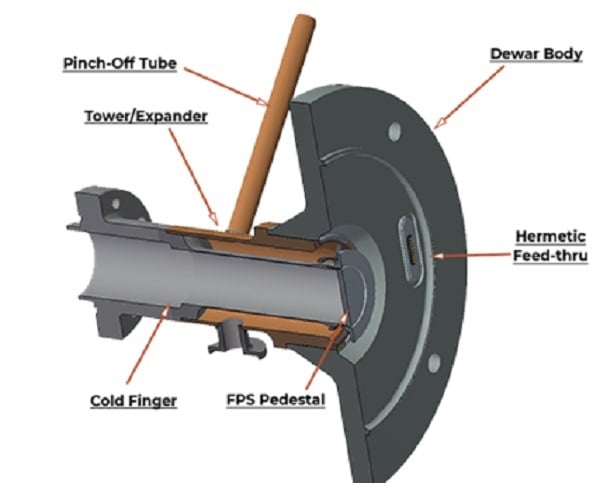

The Qnnect Pacific Aerospace & Electronics Division (PA&E) specializes in the development and production of several components and applications used together with dewars, such as integrated electronics, hermetic connectors, EMI filters and other materials that require specialty bonds and welds. A typical dewar – as shown in Figure 1 – is comprised of several elements, including the dewar body, a tower or expander, an FPS pedestal, a cold finger assembly, hermetic feedthroughs, window mounts and shrouds and pinch-off tubes. These components must be designed, qualified and tested to withstand extreme shock, vibration and thermal cycling environments, while maintaining a vacuum environment to protect and ensure the efficient operation of the FPA. Because IR cameras, their FPAs and operational environments are application-specific, dewars are custom-designed and built to each unique set of user specifications. Consequently, there are several challenges that an IR camera designer must address when designing and building a custom dewar.

Figure 1. Dewar components. Source: Qnnect

Figure 1. Dewar components. Source: Qnnect

Custom dewar design and fabrication challenges

Every component in the dewar assembly is designed, fabricated and assembled to precise specifications. Typically, a customer with a cooled dewar application would choose from a limited number of providers, each specializing in a different component of the dewar (e.g., cold finger, connector, pins, etc.) or manufacturing process (e.g., laser welding, brazing, assembly, testing, etc.) Qnnect offers an alternative to this multi-vendor approach that consolidates the manufacture and assembly of a turn-key dewar at a single location with a single vendor. Some of the design and fabrication considerations for custom dewars include the following:

Size and packaging constraints

The end component requirements will usually define the necessary size for the dewar as part of the overall IR system, including large, small and high pixel count formats. Size and packaging constraints are often dictated by limitations of the dewar fabricator’s machining equipment. Qnnect has produced several dewar formats in a variety of sizes.

Materials

Although it is challenging to precisely mill dewar components using stainless steel, titanium, aluminum and copper, special consideration must be given to alternative or specialty materials with regards to welding, hermetic sealing and machining. Qnnect has experience with several unique solutions to provide compatibility:

· An explosively bonded metal option that enables manufacturing of dewar electronic connectors that can be welded into titanium or aluminum.

· A proprietary material, Kryoflex(R), which is a polycrystalline ceramic, enables sealing of high conductivity pins into lightweight connectors and housings. Connectors sealed with Kryoflex provide a robust hermetic seal without the worry of failure due to a cracked glass seal.

· Qnnect uses a solid-state laser welding process that results in a highly reliable hermetic seal, eliminating the use of solder flux and the danger of failure due to solder fatigue.

· Qnnect is very experienced in the use of thermally stable and thermally conductive materials like aluminum nitride (AlN) to support high performance cooling.

Differential thermal expansion

Using materials with different coefficients of thermal expansion (CTE) can be a hazard to the longevity of the dewar. Qnnect tests each component of the dewar to perform reliably between -65° C and 200° C. Qnnect only uses materials with matching CTE’s so they will react to temperature changes in a very similar manner. Internal assemblies and construction proven to survive cryogenic temperatures of approximately 77° K.

Electrical connector compatibility

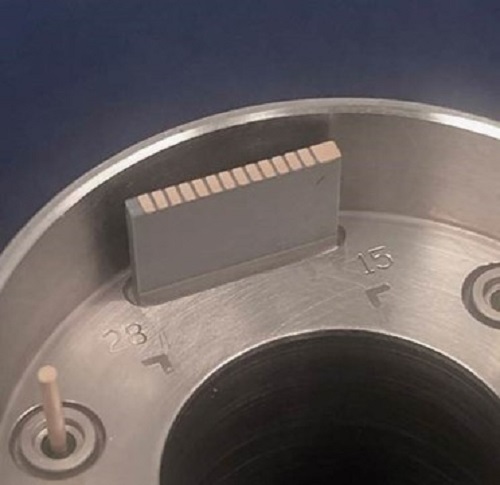

PA&E, a Qnnect company, has been manufacturing ultra-high-vacuum and cryogenic qualified hermetic connectors and feedthroughs for decades. They offer several interconnect options to ensure optimal electrical performance and hermetic reliability. For example, some customers require single, individually placed pins sealed into specific parts of the dewar body. Other designs may benefit from a standard interface, such as Qnnect’s hermetic Micro-D, Junior-D and Nano-D connectors that will satisfy a variety of requirements. Applications that require very high-density coplanar wire-bond surfaces will want to explore the use of high-temperature co-fired ceramic (HTTC) feedthroughs that are integrated into dewar bodies using Qnnect’s unique hermetic brazing process (Figure 2).

Figure 2. HTTC feedthroughs. Source: Qnnect

Figure 2. HTTC feedthroughs. Source: Qnnect

Hermeticity

All components and the final dewar assembly are tested to a meet a maximum leak rate of 1 X 10-9 (He) at 1 ATM. This includes those pieces that are brazed, laser-welded and connectors sealed with our Kryoflex ceramic seal, which has been which has been proven hermetic to 1 X 10-13 (He) at 1 ATM differential in the field.

Environmental qualification

All dewars must be qualified for operation when exposed and tested in a variety of environments that are specified according to the application and customer requirements including shock, vibration, thermal, vacuum and electromagnetic environments. Dewars must also be qualified for MIL-STD-202, which consolidates all of the individual test methods for electronic and electrical component parts and MIL-STD-883, which establishes uniform methods, controls and procedures for testing microelectronic devices suitable for use within military and aerospace electronic systems.

Qnnect overview

Qnnect is a leading global producer of highly engineered electronic interconnect solutions for high-density and high-speed applications of leading original equipment manufacturers. Qnnect’s connector and interconnect businesses have over 100 years of combined experience as trusted partners in the defense and aerospace, Hi-Rel, semiconductor, test and measurement and consumer electronics markets. This experience and expertise not only allow Qnnect to design and fabricate each key dewar component, but to also assemble and test each assembly before being delivered to their customers. More information about their products and capabilities can be found on their website.