Booming consumer demand for portable devices is storing up a battery waste disposal problem for the future

Batteries are a convenient, high-density store of energy. It is no accident that they are a mainstay of connected wireless and IoT devices. There is, however, a lot not to like about batteries:

* Size and shape – cylindrical or coin cell batteries have a bulky form factor that can be hard to accommodate in consumers’ preferred sleek and ultra-thin designs.

* High total cost of ownership – when a battery is fully discharged or reaches the end of its cycle life, its replacement in industrial or commercial products calls for the attendance of a technician onsite, an event that can cost as much as $200 per unit.

* Damaging environmental footprint – batteries contain harmful or toxic chemicals. Disposal at the end of life is difficult as the materials in batteries are hard to recover and recycle.

* Exposure to onerous compliance requirements – governments are taking an increasingly aggressive stance towards the environmental harms caused by batteries and the regulatory environment for products containing batteries looks set to become more hostile in the coming years.

These factors explain why manufacturers of small, connected devices are looking to a combination of energy harvesting (most often a photovoltaic cell) and a supercapacitor as a cheaper, maintenance-free alternative to a battery power supply.

Sizing up supercaps

An energy harvester alongside a traditional cylindrical supercap eliminates the high cost of battery replacement and frees the OEM from the obligation to comply with regulations governing embedded batteries. However, this approach falls short on two other problems associated with batteries:

* Traditional supercaps are bulky and limit mechanical design freedom in the same way that a battery does.

* Traditional supercaps contain a damaging mix of toxic materials and persistent ‘forever chemicals’, and are hard to recycle.

Innovations in chemistry and production have enabled the development of a new type of pouch supercap: completely non-toxic, fully recyclable and ultra-thin. This provides design freedom and is a suitable size for use even in smart cards. Pouch supercap technology offers a green and space-saving way to eliminate a battery from a new smart device design.

Environmental burden

The motivation for OEMs to avoid batteries is growing ever stronger. The problem of batteries’ environmental footprint is becoming increasingly acute because of the rising volumes of batteries being made and – eventually – disposed of. Smart devices and most wireless and IoT devices need an autonomous, wire-free power supply; today, the battery is the OEM’s default choice.

Figure 1: Materials inside the Ligna Energy supercaps are bio-based

But this is storing up a gargantuan e-waste problem. According to the European Commission, in 2022, 244,000 tonnes of portable batteries were sold in the EU. In the same year, only 111,000 tonnes of used portable batteries were collected for recycling.

Batteries are far from benign when they reach their end of life and enter the waste disposal system. Most contain chemicals that are toxic or harmful to humans and wildlife, including lithium, manganese and cobalt, as well as heavy metals and PFAS (per- and polyfluoroalkyl substances). The potential harm at the end of life is matched in the battery production process as well. Mining the materials used in the production of batteries is itself often environmentally damaging and users of these materials are at risk of breaching standards requiring the avoidance of conflict minerals.

No wonder, then, that forward-thinking governments are introducing regulations aimed at reducing the harm from the large-scale production and disposal of batteries.

For example, the EU’s latest Batteries Regulation 2023/1542 is aimed at ensuring that, “in the future, batteries have a low carbon footprint, use minimal harmful substances, need less raw materials from non-EU countries, and are collected, reused and recycled to a high degree in Europe”. Other regulations are either in force or under consideration in jurisdictions around the world.

The scale of the battery problem is set to get worse as the number of IoT objects increases from billions to trillions. The trend is for IoT products to become ever smaller and thinner, making it harder to maintain the safe operation of lithium-based batteries and to enable reclamation of materials at the end of the device’s life.

Product redesigns

An energy harvesting system with a supercap as the energy storage element, replacing a battery in a smart device, provides ‘forever power’, eliminating the high expense associated with the replacement of a discharged battery. It also exempts OEMs from the duty to comply with regulations on batteries.

The use of a conventional supercap leaves open the question of potential environmental harms. Traditional supercaps commonly contain heavy metals and PFAS. Some even use lithium as an electrode material or lithium salts in the electrolyte.

In addition, the standard form factor is cylindrical, with a substantial diameter that limits the ability of the product manufacturer to create a lightweight and ultra-thin design. A typical example supplied in a cylindrical form factor would be 8mm long with a diameter of 20.5mm.

These dimensions allow for the supercaps to be embedded in products such as electronic shelf labels, asset trackers, smart cards and smart thermostats.

Bio-based materials

Now a solution to the multiple problems inherent in the use of embedded batteries has emerged from a combination of innovations in manufacturing technology, product design and material composition. The S-Power family of supercaps from Ligna Energy results from research and development aimed at finding a non-toxic, recyclable and sustainable alternative to traditional supercaps.

Today, all the materials used in Ligna Energy S-Power supercaps are completely safe and non-toxic, and can be safely disposed of with no risk of harm to people or wildlife. The supercaps are compatible with standard recycling or disposal methods, including shredding or burning.

Today, all the materials used in Ligna Energy S-Power supercaps are completely safe and non-toxic, and can be safely disposed of with no risk of harm to people or wildlife. The supercaps are compatible with standard recycling or disposal methods, including shredding or burning.

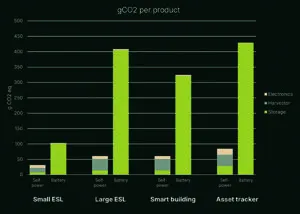

The greenhouse gas footprint of an energy harvesting system based on a PV cell and an S-Power supercap is much lower than that of a battery power supply (see Figure 1). Comparing a power supply based on S-Power 2S supercap(s) and a PV cell with a battery power supply based on two AAA batteries replaced once during the host product’s lifetime, the estimated carbon footprint of the Ligna Energy solution is between 27g and 49g CO2e, whereas for the AAA battery system it is 223g CO2e.

About The Author

John Söderström is marketing director, Ligna Energy