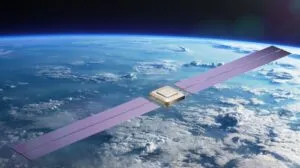

SpaceWERX is the U.S. Air Force space technology accelerator programme. And the requirements are for a fast to manufacture, multiorbital solar array wing concept. The organisation awarded a Direct-to-Phase II contract.

Radiation-hardened

Solestial says it will be optimising its low-mass, radiation-hardened silicon solar cells and solar power modules for fast assembly. It will also develop novel module electrical interconnectors.

Solestial says it will be optimising its low-mass, radiation-hardened silicon solar cells and solar power modules for fast assembly. It will also develop novel module electrical interconnectors.

The end result will be construction and testing of a complete solar array wing.

The project will culminate in a two-week production sprint to manufacture 1 kilowatt of solar cells and modules. This will be followed by a two-week solar array assembly and integration run. Basically, the goal is manufacturing a complete solar array wing within one month’s time.

Faster?

“This is a meaningful award for us that will result in critical research and development benefiting the U.S. Space Force,” said Solestial CEO Margo de Naray.

“Long manufacturing lead times have plagued the incumbent solar technology for space. Through our use of affordable, accessible silicon and automated manufacturing of solar cells and solar power modules, Solestial is uniquely positioned to solve this critical bottleneck and support mission readiness.”

Solestial

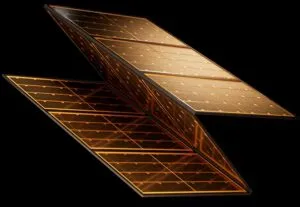

The company’s solar power modules are adaptable to both Z-folded and roll out arrays.

The company’s solar power modules are adaptable to both Z-folded and roll out arrays.

The latest contract brings Solestial’s total for awarded contracts to $7 million. This is for Small Business Innovation Research (SBIR) contracts from the U.S. Space Force, U.S. Air Force, Air Force Research Laboratory, NASA, and the National Science Foundation.

The company headquarters are in Tempe, Arizona, USA. It shares Arizona State University MacroTechnology Work’s 7,000 square foot solar laboratory. This is home to company’s solar cell production line.

See also: Orbital wins $1.7m Space Force contract to manufacture antennas in space