S. Himmelstein | June 19, 2023

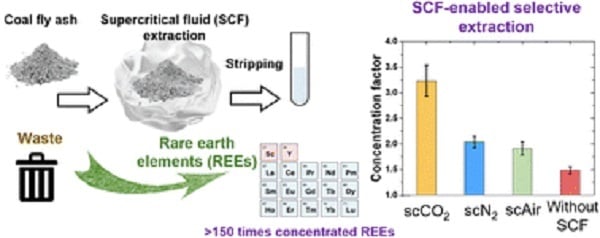

The supply of the rare Earth elements (REEs) widely consumed to engineer electronic devices and renewable energy systems is limited, prompting researchers to seek alternative avenues for their production. Recognizing landfilled coal fly ash as a valuable resource, with an average total REE concentration as high as 1,220 ppm, researchers from Washington University in St. Louis devised an efficient process for their extraction.

The supercritical fluid extraction process developed was demonstrated to recover REEs and easily separate impurities by use of carbon dioxide, nitrogen and air as supercritical fluids. The application of supercritical CO2 was observed to be particularly effective in decreasing the concentrations of impurities in the final product, especially calcium, magnesium and aluminum. A multistage stripping process used to collect REEs further separated the elements of interest and impurities to increase the purity of REEs in the collected solutions.

The process recovers valuable and critical resources from coal waste materials. Source: RSC Sustainability (2023). DOI: 10.1039/D2SU00033D

The process recovers valuable and critical resources from coal waste materials. Source: RSC Sustainability (2023). DOI: 10.1039/D2SU00033D

The final products contained up to 6.47% REEs, compared with 0.0234% in the initial coal fly ash source. The method described in RSC Sustainability eliminates the need for elevated process temperatures and the use of strong acids for target element extraction.

This environmentally benign process could contribute to the recovery of REEs with an estimated value of $4 billion contained in the more than 79 million metric tons of coal fly ash generated in the U.S. annually.