These products now need to possess enhanced capabilities such as miniaturization, integration, resistance to high voltage, and high transmission speed.

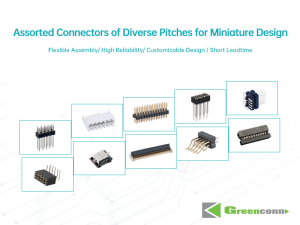

Miniature Connectors

Today, Electronic products are becoming increasingly compact, which drives the development of connector miniaturization. The connector’s downsizing and thickness can not only lower costs, but also provide more layout space for the device and make it easier to configure more intelligent functionalities. At the same time, it raises the bar for design, machining accuracy, and the manufacturing process. Greenconn, a leading connector and cable producer since 1998, has focused in the development of automotive connectors for more than 26 years, with consistent production of varied product pitches spanning from 0.4mm to 8.5mm, and continues to create advances in micro-miniature connectors.

Integrated Connectors

With the aim of saving space and enhancing system reliability, connectors are progressing towards integration by combining multiple functions into a single unit. For instance, integrating power supply and signal transmission capabilities enables the seamless flow of current while simultaneously fulfilling signal transmission demands. The GGAC203 series floating board to board connectors from Greenconn flawlessly incorporates this feature, allowing for a flexible and precise layout that is also highly compact.

High Power Connectors

Electrification has increased the demand and development of high-voltage and high-current connectors. This connector is commonly used in automobile vehicle systems and charging systems. The long charging time, in particular, has an impact on user convenience and has become a major impediment to electrification growth. To satisfy the need for quick charging, the charging device is also showing a trend of high power. As a result, high power connectors used in the automotive manufacturing industry must exceed stringent electrical, mechanical, and environmental performance standards.

High-Speed Connectors

High-frequency/high-speed connectors are mostly utilized in industries requiring high-speed signal transmission, such as 5G communication and autonomous driving. The intelligent networking of autos has significantly increased demand for high-speed connectivity. With the advancement of electric vehicles in autonomous driving and the expansion of in-vehicle entertainment setups, the demand for signal and energy transmission is also growing. How to assure high-speed and robust signal transfer across systems in high-speed environments has become a major challenge for connector manufacturers and end users. Greenconn timely responded to this need by launching a series of high-speed BTB/WTB connectors with exceptional signal integrity.

Over time, automotive connectors will shift from standardization to personalization and customization. Due to the high requirements on safety, stability, and functionality, automotive connectors are becoming more tailored. To successfully finalize a customized automotive connector, connector manufacturer designers and automotive connector demand merchants must work closely together. To this end, Greenconn utilizes a variety of simulation applications to create product models and accompanying boundary conditions, and conduct simulation analysis and validation of the connector’s mechanical, electrical, and high-frequency performance. This approach effectively cuts down on the costs of product development failures caused by issues such as incorrect material choices and flawed structures, while simultaneously enhancing the likelihood of successful development.

With extensive experience in automotive connectors, Greenconn always prioritizes serving customers by providing top-quality products that cater to their specific requirements, while dedicated to developing customized solutions that are suitable, functional, and user-friendly for a wide range of automotive applications.

Author information

![]()

Website: https://www.greenconn.com

Contact: sales@greenconn.com