There are five basic motors, ranging from 36 x 36mm (7 or 12mm bore) to 60 x 60mm (27mm bore):

| size (mm) | 36×36 | 42×42 | 57×57 | 60×60 | |

| Shape | round | square | square | square | square |

| Bore (mm) | 7 | 12 | 16 | 22 | 27 |

All of the motors measure 21mm from front to back, plus 8mm of shaft protrusion.

In each case there is a standard and a higher torque variant, for example, the 42mm HS17HX7L4100, and its higher torque 42mm cousin VHS17HX7L4100.

Torque figures for the motors vary between different Moons sources – Electronics Weekly has asked for clarification, so watch this space or check for yourself if this information is important to you.

“The large bore diameters of Moon’s hollow shaft stepper motors opens up many design possibilities, allowing for the integration of linear transmission shafts, cables, air flow, liquids, or even [light] beams directly through the centre of the motor,” according to the company. “When paired with a harmonic gearbox, these hollow shaft motors deliver output torque levels nearly matching those of our solid shaft motors.”

“The large bore diameters of Moon’s hollow shaft stepper motors opens up many design possibilities, allowing for the integration of linear transmission shafts, cables, air flow, liquids, or even [light] beams directly through the centre of the motor,” according to the company. “When paired with a harmonic gearbox, these hollow shaft motors deliver output torque levels nearly matching those of our solid shaft motors.”

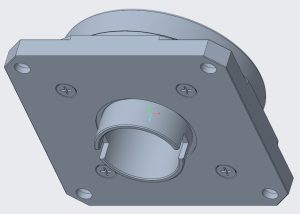

Shaft ends can be a plain tube, have two slots for bayonet-style torque transmission (right), a flange with four threaded holes in an axial direction, or a flange with four radial threaded holes.

Applications are foreseen in robotics, semiconductor manufacturing, industrial automation and security systems.

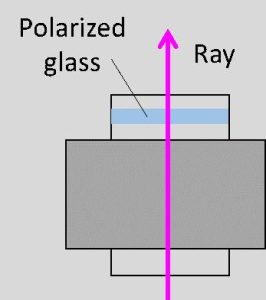

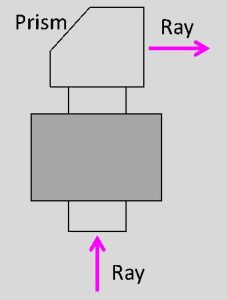

Optical use is emphasised, with the motor rotating a polariser for beam passing down the bore in one example (above left), or the motor used with a right-angled prism to convert an axial beam into a radial scan (left – imagine line-scanning the inside of a pipe).