Metamaterials are artificial composite materials composed of at least two different materials. They possess a large number of tiny material structures that are arranged to form a 3D structure. Each of these individual structures is known as a ‘meta-atom’ and possesses properties that are not found in natural materials, including the ability to control electromagnetic waves.

Metamaterials are artificial composite materials composed of at least two different materials. They possess a large number of tiny material structures that are arranged to form a 3D structure. Each of these individual structures is known as a ‘meta-atom’ and possesses properties that are not found in natural materials, including the ability to control electromagnetic waves.

The bending of electromagnetic waves is usually in a positive direction relative to the direction of incidence. This is known as a positive refractive index. The main feature of a metamaterial, however, is that they have a negative refractive index. Meta-atoms are smaller than electromagnetic wavelengths, so they cause a negative bending of any electromagnetic waves that pass through them. This is unique to metamaterials.

Classifying metamaterials

Metamaterials are typically classified into two types. The first is wave metamaterials that control wave propagation and the second is diffusion metamaterials that control diffusion processes (Figure 1).

Figure 1: Graphical representation of different types of metamaterials [Source: YongAn Huang]

Metamaterials can control different electromagnetic waves – such as sound or light waves – across a range of applications. Metamaterials are known to have a range of properties, including the ability to control the direction of electromagnetic radiation. They possess unique properties, such as a negative refractive index, but also electromagnetic cloaking and negative permitivity and permeability properties.

Thermal metamaterials can bring a lot of benefits to electronic design. Electronic components are easily damaged by intense heat and the emergence of nanoelectronics, 3D integrated circuits and flexible electronics is making thermal management difficult in these complex architectures.

They can be used to improve thermal dissipation, provide thermal shielding and reduce thermal cross talk in electronic devices, as well as reflect light and prevent the rise in device temperature from outside sources – useful for aerospace, satellites and space technologies that are exposed to stronger electromagnetic waves.

Thermal metamaterials are also being used in thermoelectric devices to convert the waste heat energy (infrared waves) emitted from vehicles and equipment into electricity.

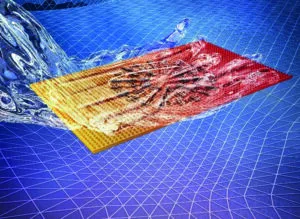

“There are three main application areas for thermal metamaterials” says Professor Jiping Huang, department of physics, Fudan University “Thermal metamaterials can be used for thermal protection from infrared radiation; thermal cloaks, concentrators, and rotators can be used for more advanced thermal management; and radiation cooling films can be used for energy-free cooling.” (See Figure 2.)

Figure 2: Depiction of a thermal cloak concentrator device built with thermal metamaterial [Source: Jiping Huang]

Jiping Huang says that there are many areas that can benefit from thermal materials, such as “energy conversion systems, automotive thermal management systems, solar thermal power generation, and there is researching going into using thermal metamaterials in thermal sensors, diodes and zero-energy insulation”.

The design of thermal metamaterials relies heavily on thermotics (the sub-field of physics that is the scientific study of heat). Jiping Huang states: “The unique properties of thermal metamaterials are derived from traditional transformation thermotics and rely on complex structures and anisotropic material properties.”

This is why the properties of metamaterials are unique, because natural materials tend to be homogeneous and isotropic.

Designing thermal metamaterials, however, is not straightforward. Jiping Huang also notes that “traditional fabrication techniques for thermal devices are often tied to specific geometries and layered structures, which limit their flexibility in fabricating complex or irregular shapes, such as metamaterials”.

Jiping Huang goes on to say that “numerical optimisation, deep learning and topology optimisation methods have enhanced the performance and adaptability of thermal metamaterial devices, while conformal transformation theory reduces the geometric constraints in metamaterial design”.

There are already commercial metamaterial systems in use, but Jiping Huang believes that “the future design of thermal metamaterials is expected to become smarter and more efficient. With the rapid advancement of technologies like artificial intelligence and deep learning, the design process will become increasingly automated and intelligent so that non-linear designs can be created that are able to integrate multiple thermal functionalities into the same device.

“This is in addition to thermal metamaterials being integrated with other types of metamaterials where each material enables multifunctionality.”

It is thought that thermal metamaterials will soon be used across the electronics, energy and healthcare space as the industrialisation of metamaterial production accelerates.

Acoustic metamaterials

Acoustic metamaterials use phononic crystals to control, manipulate and direct sound waves (phonons). Acoustic metamaterials have an anisotropic mass and a negative density and are used for vibration damping, imaging, medical ultrasound, anti-sonar technologies and wireless power transfer. Phonons are also responsible for thermal conduction in solids, so acoustic metamaterials can be designed to control heat transfer in electronic systems.

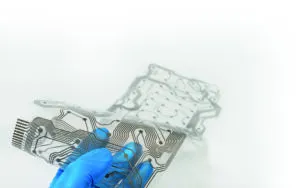

Figure 3: The different application areas of flexible metamaterials showing the different application pathways possible [Source:YongAn Huang]

Active acoustic metamaterials provide a degree of control over sound waves that is beyond the capabilities of passive devices and are dynamically reconfigurable and can compensate for any loss in wave intensity.

There are applications that lie outside the scope of electronics design, but acoustic metamaterials can be designed to trap or transmit specific frequencies of sound waves. Using metamaterials in this way can help to design more advanced acoustic resonators for a range of technologies – such as musical instruments and advanced medical imaging. Acoustic metamaterials can also precisely control the deformation of acoustic fields and be used to hide or cloak objects from sound waves.

Electromagnetic metamaterials

Metamaterials can control a range of electromagnetic waves across the electromagnetic spectrum in a single device, enabling metamaterials to become programmable. Each of the meta-atoms can manipulate different electromagnetic waves to build a device that has multiple electromagnetic functions. Each meta-atom can control a certain wavelength and the functions can be controlled with advanced software.

In development

Programmable metamaterials are being developed that can autonomously adapt to their environment and communicate with other metamaterials in a system to build advanced devices that can provide sensing, imaging or communications functions. Some examples of applications include medical imaging and wireless communications.

There are different ways to develop programmable metamaterials, but one common approach is to build systems that mimic FPGAs. The challenge with programmable metamaterials is creating a device that has a refresh rate that can change the properties of the metamaterial in real time in high frequency environments – such as THz waves. The refresh rates between applications vary, but are typically in the KHz to MHz ranges.

Is flexible the future?

With flexible and smaller electronic devices becoming more commonplace, metamaterial designs are also having to bend, stretch and roll to be used in the next generation of devices. This is achieved by incorporating metamaterials on to flexible substrates such as low surface energy polymers.

Introducing flexibility into the metamaterial design also opens the door to fabricating transparent metamaterials for remote sensing, imaging and optical resonator devices.

Introducing flexibility into the metamaterial design also opens the door to fabricating transparent metamaterials for remote sensing, imaging and optical resonator devices.

Prof YongAn Huang, vice director, state key laboratory of intelligent manufacturing equipment and technology, Huazhong University of Science and Technology, tells Electronics Weekly that “flexible metamaterials could be used to enhance existing flexible electronics used in wearable electronics, epidermal electronics, implantable electronics, soft robotics and aircraft smart skins. It’s becoming increasingly challenging to improve flexible electronics with conventional strategies, but metamaterials are breaking new ground.”

YongAn Huang also states that there are many types of flexible metamaterials that can be fabricated based on the classifications of bulkier metamaterials, including “flexible mechanical metamaterials, flexible optical metamaterials, and flexible acoustic metamaterials, with their use potentially spanning interesting application areas such as acoustic superlenses, invisibility cloaks, e-skins and e-eyes”.

There have been many design considerations for developing flexible metamaterials that revolve around heuristic design (based on previous experience) and rational design (based on the target properties in mind). On heuristic design, YongAn Huang says: “Bioinspiration has been proved powerful and effective to develop novel metamaterials.” Rational design has revolved around topology optimisation and “topology optimisation optimises structure layout within a given design space, and it is mostly used at the concept level of a design process. A hybrid approach of heuristic and rational design methods with computer-aided design techniques is expected to be a promising approach.”

The maturation of flexible metamaterials is not as established as bulk metamaterials. YongAn Huang tells Electronics Weekly that “many demonstrated functionalities and device prototypes in this field are still very preliminary and are mostly limited to laboratory research, or sometimes just for theoretical performance under ideal assumptions without consideration of real applications. Many of the available fabrication techniques – 3D printing, laser cutting, two-photon lithography – are still at an early stage for developing flexible metamaterials, but combining top-down and bottom-up techniques may enable smaller-scale metamaterials.”

While the field is still relatively new, YongAn Huang concludes that “should the current growth trend in flexible metamaterial design/device integration research continue, we believe it is not inconceivable for the field to witness a near-explosion in industrial interest. The world is curvy, dynamic and variable, yet our industrial civilisation is built upon flat technological foundations, but metamaterials open a brand-new direction to design the capability of materials at will.”

FACT FILE

* Metamaterials are being developed for a range of industries, from medical to automotive and aerospace industries.

* Uses include biosensors to antennas, energy harvesters, optical filters, smart power management devices, remote monitoring devices, smart power management and shielding devices.

* Metamaterials and metasurfaces are similar and both contain meta-atoms, but metasurfaces are 2D, whereas metamaterials are 3D.

* Metamaterials can be programmable; they control a range of electromagnetic waves across the electromagnetic spectrum in a single device.

About The Author

Liam Critchley is an independent technology journalist