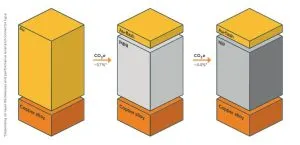

Branding the plating stack Econidur, “according to TE internal analysis and calculations, in alignment with ISO standard 14067/14040/44, CO2 emissions decrease over 44% compared to a precious metal plating, depending on layer thicknesses, performance level and connector type”, said the company.

Electronics Weekly has requested more information on the exact plating stacks involved in this comparison – until then, see the diagram above for some of the limited additional information available.

Is it robust?

“Econidur plated connectors will function reliably in many industrial applications over a long period of time – in automation control applications and motor control systems, for example”, said TE. “They support reliable signal transmission up to several Gbit/s and feature withstand capabilities in terms of vibration in the long-term, gas influences and micro friction. Overall, Econidur plating reaches in minimum the same characteristics as a precious metal plating layer. For fretting and vibration resistance, Econidur plated products are a reliable choice.”

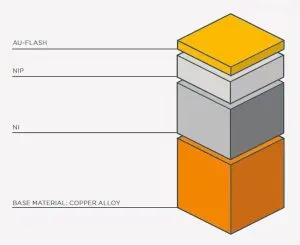

The diagram on the left is of a stack with an additional layer of pure nickel layer under the nickel-phosphorus, which the company is also giving the new branding.

The diagram on the left is of a stack with an additional layer of pure nickel layer under the nickel-phosphorus, which the company is also giving the new branding.

Electronics Weekly has asked how different versions of Econidur compare with C02 and durability – watch this space for clarification if the company is forthcoming.