Researchers in Japan have micro-fabricated a thermoelectric generator for IoT devices from non-toxic materials.

Researchers in Japan have micro-fabricated a thermoelectric generator for IoT devices from non-toxic materials.

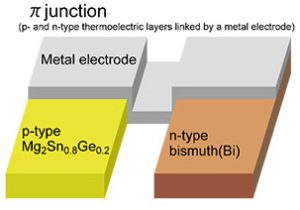

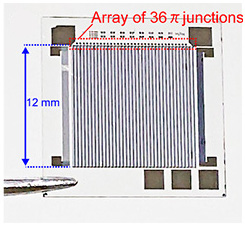

The proof-of-concept consists of 36 junctions, each made from p-type Mg2Sn0.8Ge0.2 working against n-type bismuth.

“The output voltages of thermoelectric conversion modules and devices generally decrease as their sizes diminish,” according to the Japanese National Institute for Materials Science (NIMS). “An approach to overcoming this miniaturisation-related issue is to create an array of π junctions in a thermoelectric device.”

With 10K across the device, it produced 50mVoc 420nAsc and 5.3nW.

Pushing this up to 110K, the figures rose to 0.58V, 4.2μA and 0.6μW – the latter being 21mW/cm2 and considered something of a record by the research team

The magnesium-based p-type material was vacuum-deposited on sapphire by molecular beam epitaxy, then patterned using photolithography followed by argon-ion milling, and reactive-ion etching.

Bismuth was used for the n-type as it can be deposited at room temperature. The coupling metal has three layers – chromium touching the p and n-type materials, backed by nickel, then covered with platinum.

NIMS worked with Japan’s National Institute of Advanced Industrial Science and Technology (AIST) and the University of Tsukuba.

The work is published as ‘Miniaturized in-plane π-type thermoelectric device composed of a II–IV semiconductor thin film prepared by microfabrication‘ in Materials Today Energy – the whole paper can be read without payment.

Image source: provided by National Institute for Materials Science